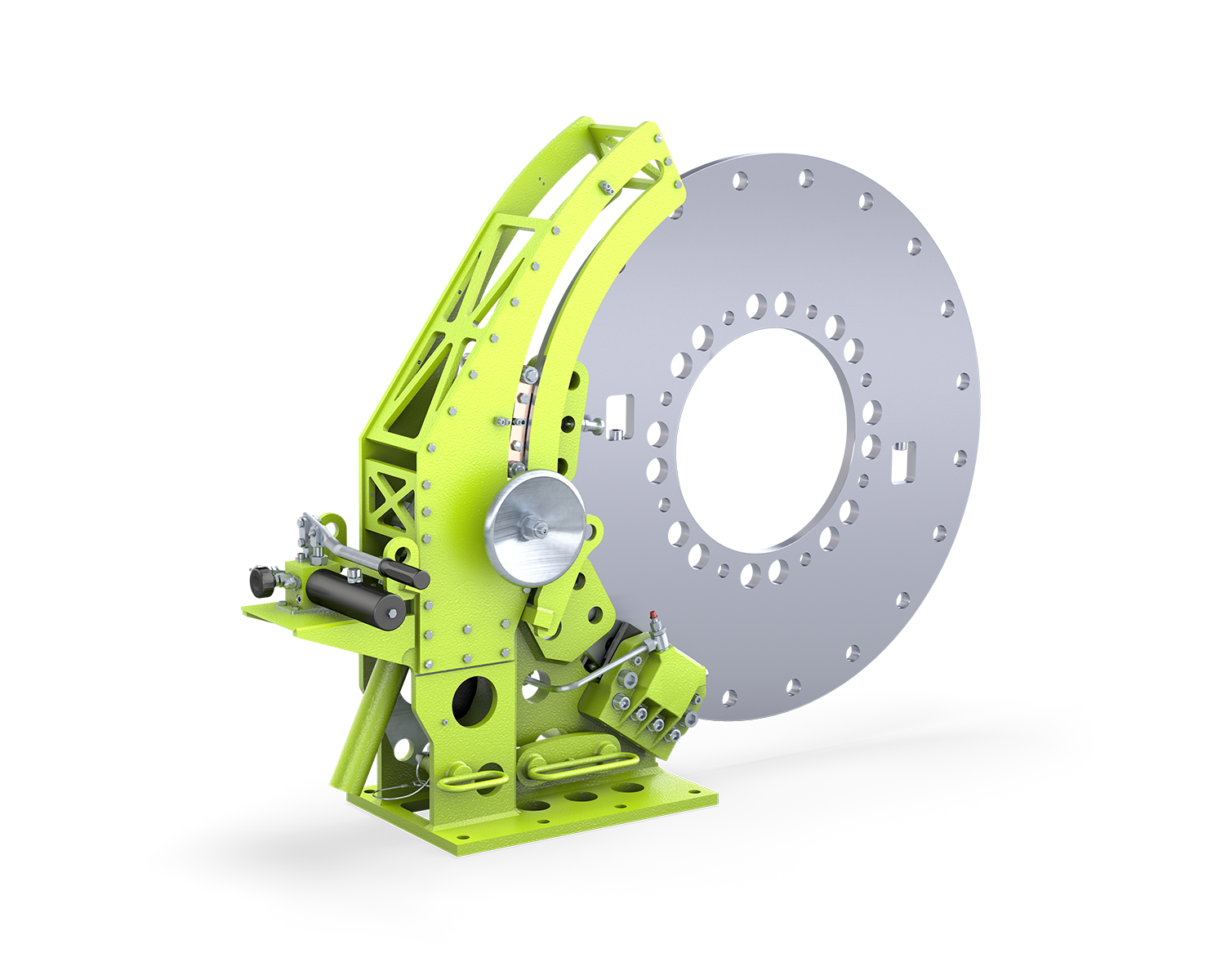

STL - Stop Turn Locking System

- Standard Range

- Stopping:

- Up to 285 000 Nm

- Turning:

- 227 000 Nm

- Locking:

- 600 000 Nm

The STL Systems are "multi-function" units, all contained within one interface. It is indeed a modular system that you can choose the function(s) needed. All from single, S (Stopping) T (Turning) or L (Locking) functions. Combined dual or triple functions in terms of SL, ST, TL, to a complete STL system can be selected. Each system contain a unique control system that communicate and integrate with superior system for easy operation and control.

- Individual stopping, turning and locking functions

- Dual functions: Stop and Turn, Stop and Lock, Turn and lock

- A complete, turning and locking system

- Control systems designed and/or customized to meet platform unique integration

- Hydraulic

- Electric

- Manual

- Standard or Custom packages

- Shock and vibration approved configurations

- Hand held control units

Whether at sea or based on land, STL Systems give you complete control over your stopping, turning and locking functions.

Stopping, Turning and Locking (STL) systems are precision engineered and fully modular, making it possible to choose from the functions to create a system which fits your application:

- Individual Stopping, Turning or Locking functions

- Dual Functions:

- Stopping & Turning

- Stopping & Locking

- Turning & Locking

- Complete STL-System with all functions

- Fully automatic control

- Semi-automatic control

- Fully manual control

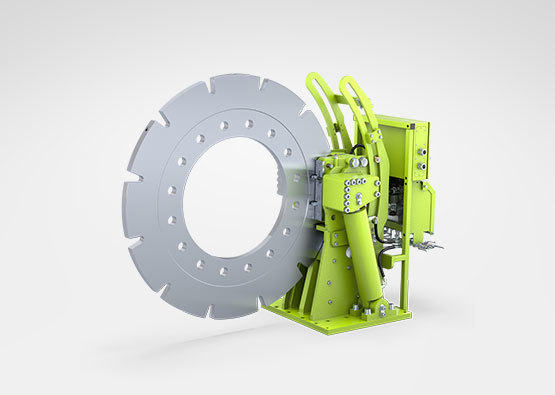

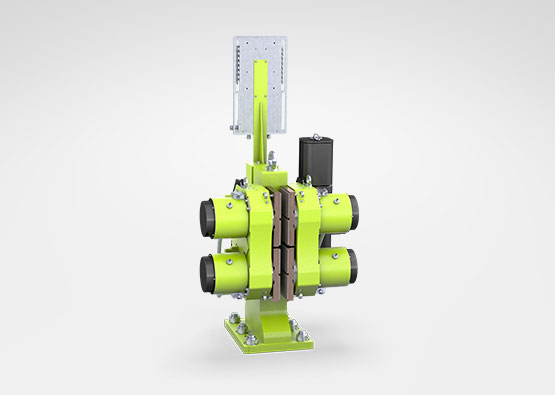

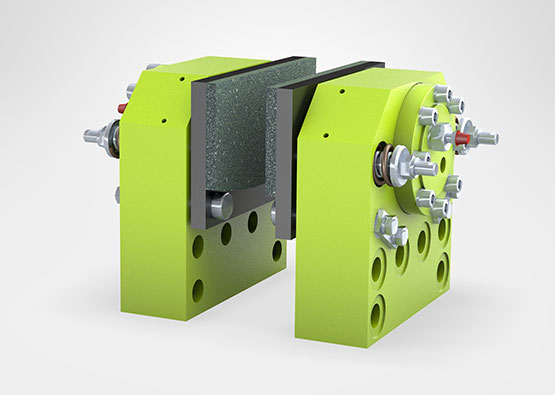

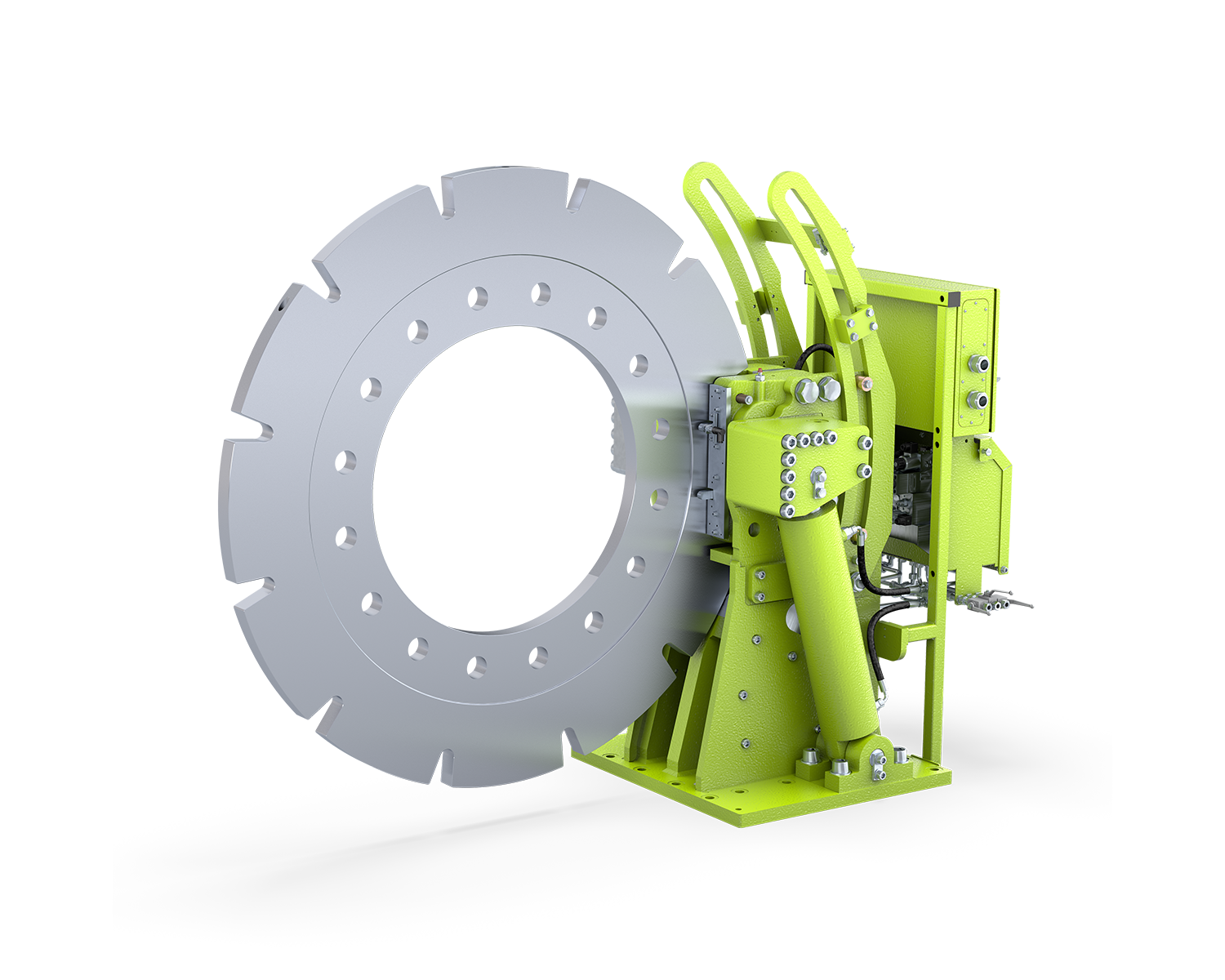

Stopping, index Turning and Locking (SiTL)

Advantages:

- Easy engagement and disengagement even with residual forces present

- Turning function is index turning with hydraulic cylinders

- Controlling can be done fully remotely, locally with push button interface, or as combination of the two controls

- Low maintenance overtime with increased personnel safety

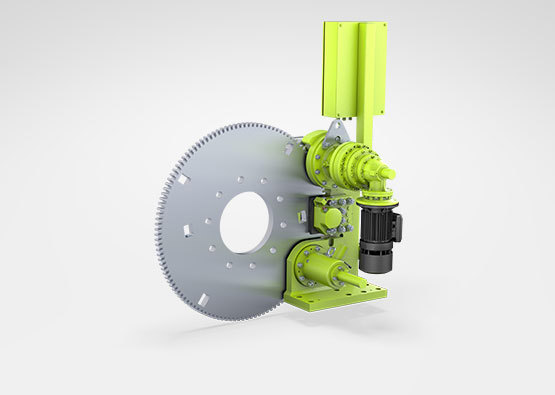

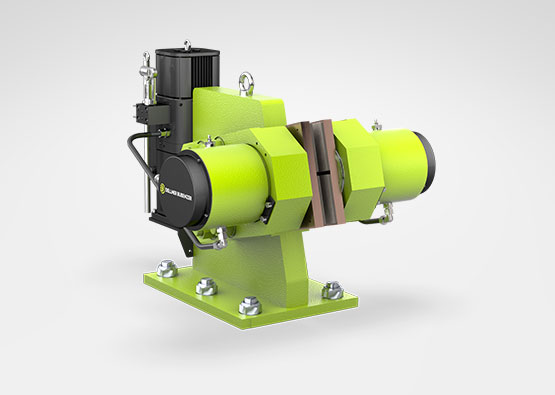

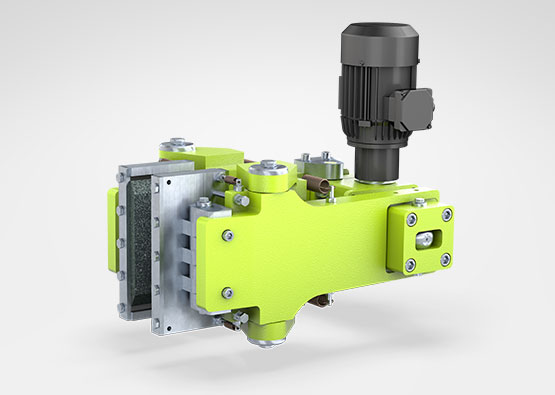

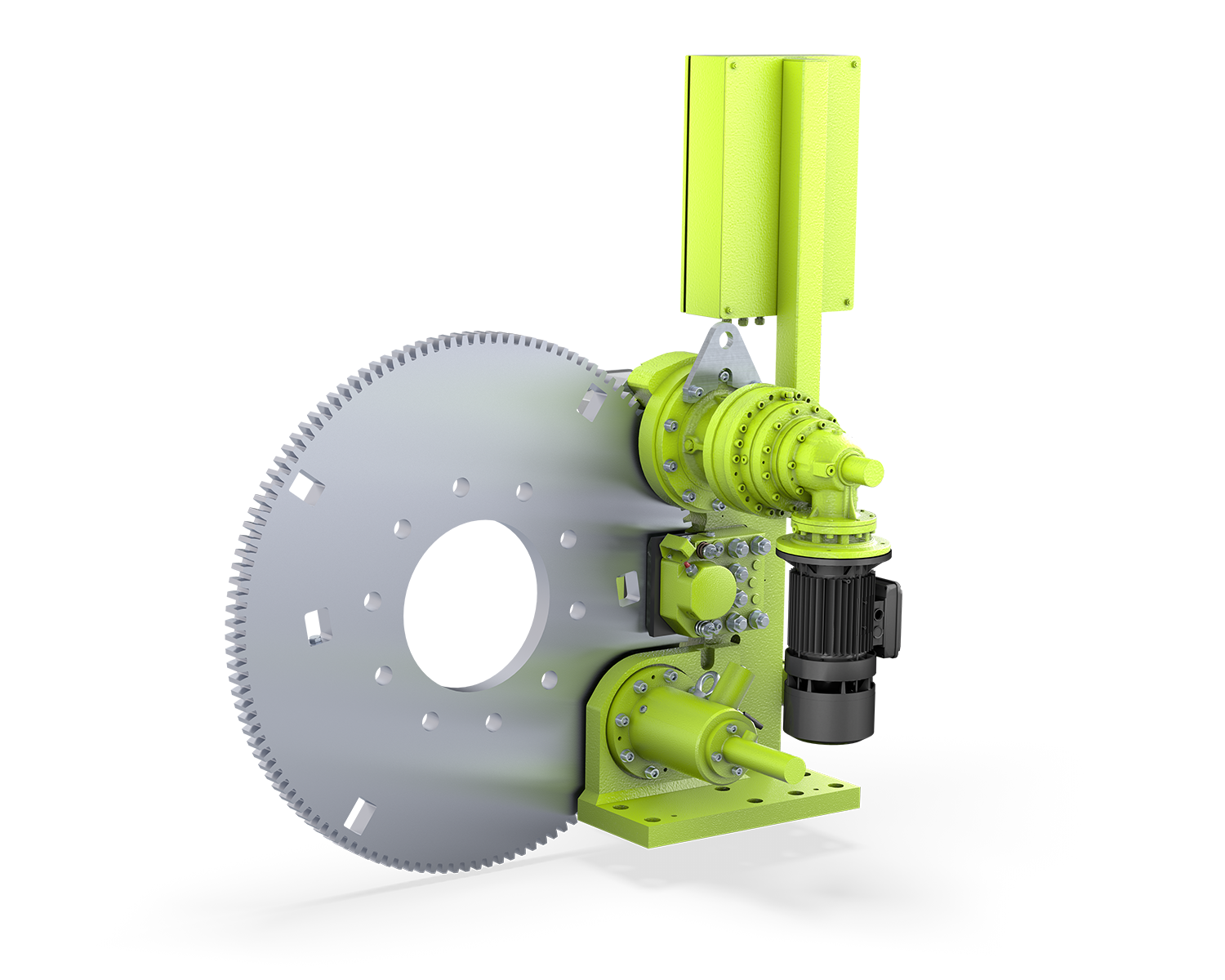

Stopping, continuous Turning and Locking (ScTL)

The electric powered continuous STL could be a preferred selection in low-range to midrange torque applications when a continuous turning operation is required and/or when manual operating has limited possibilities.

Advantages:

- Easy engagement and disengagement even with residual forces present

- Turning function is continuous turning with electric motor and gearbox

- Controlling can be done fully remotely, locally with push button interface, or as combination of the two controls

- Low maintenance overtime with increased personnel safety

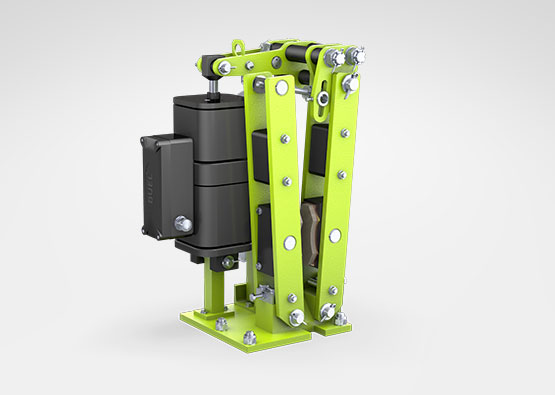

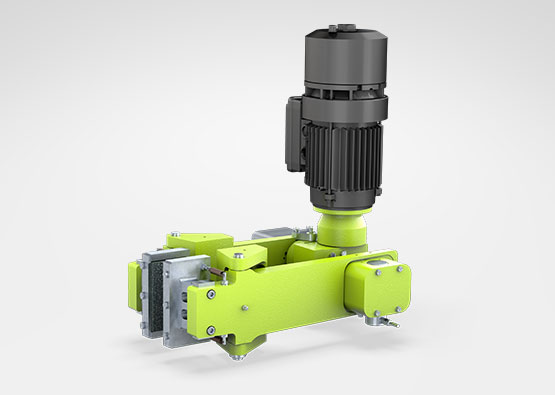

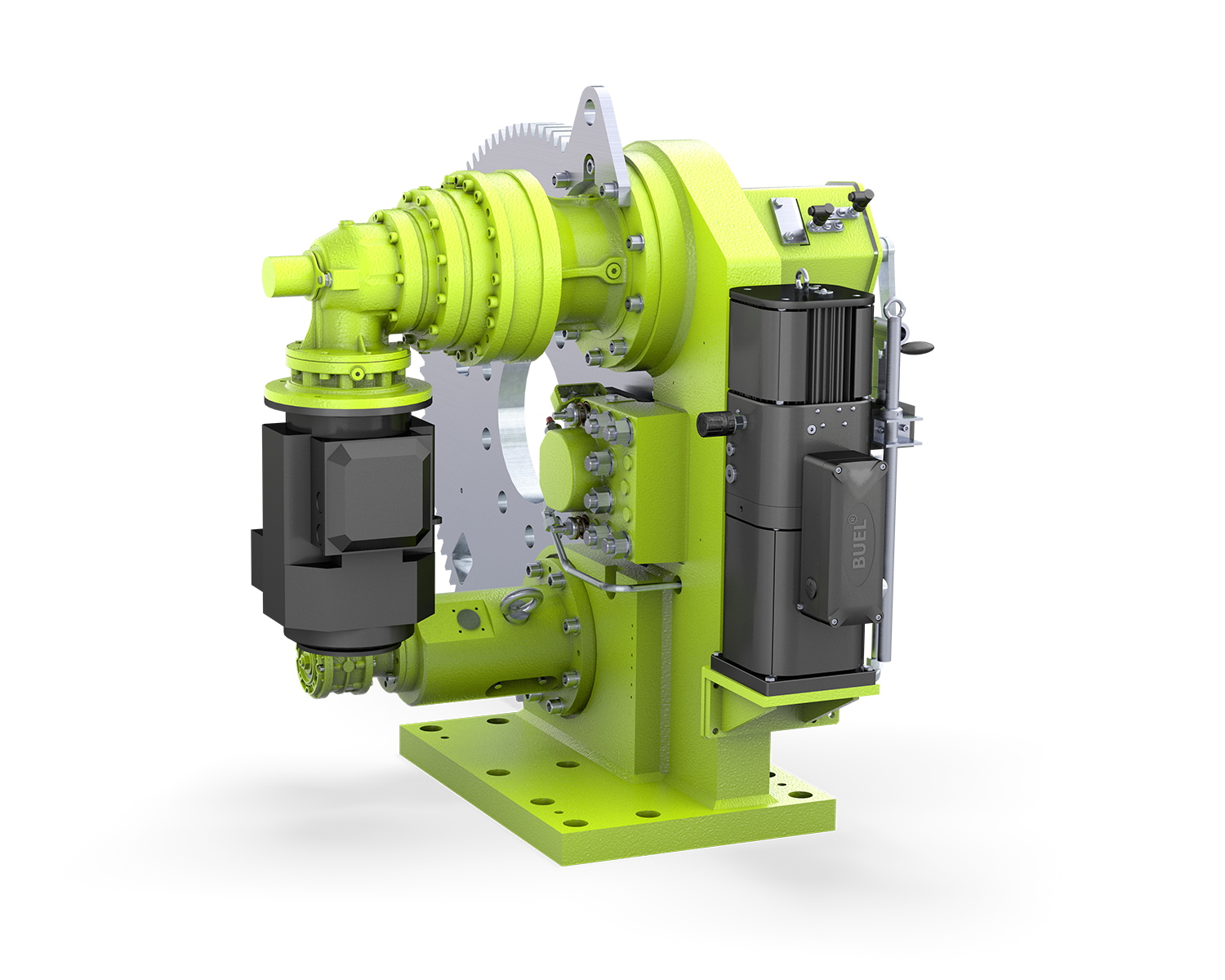

Stopping, continuous Turning and Locking (ScTL) with BUEL®

DELLNER BUBENZER’s compact, self contained BUEL® STL systems combine elements from STL with DELLNER BUBENZER’s patented BUEL® electrohydraulic thruster/power package.

Needing no external piping, the systems are compact, easy to install, and with the BUEL® using only half a litre of high performance synthetic oil (compared to up to 30 litres of hydraulic oil in standard hydraulic power units), are cheaper to run and enviromentally-friendly too.

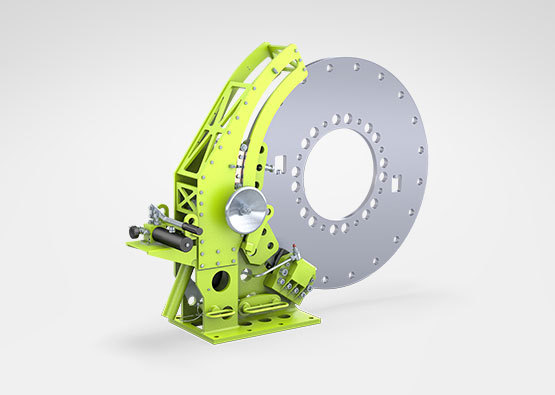

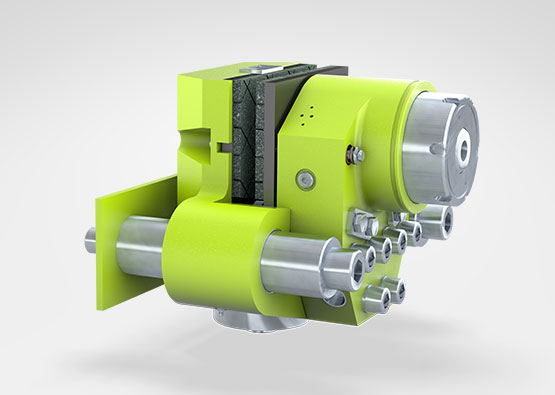

Fully Manual Stopping, index Turning and Locking (SiTL)

The electric powered continuous STL could be a preferred selection in low-range to midrange torque applications when a continuous turning operation is required and/or when manual operating has limited possibilities.

Advantages:

- Easy engagement and disengagement even with residual forces present

- Turning function is indexed turning with fully manual control

- Controlling is done fully locally, with provision for instruments for status detection (interlock)

- Fully independent from external power sources

- Low maintenance overtime with increased personnel safety

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

Supported by decades of engineering, evolution, and innovation, the SB 28.5 brake presents significant advantages with an enhanced and compact design, sustainability, and preeminent performance.

The SB 30 is the most powerful service brake in this series. It is dimensioned for large hoists and for BOSS applications. Furthermore, automatic adjustment, self-centering, jaw parallel adjustment are part of the standard equipment.

The SB 8 series covers a large part of the versatile industrial applications. It is often used in hoists where installation space is limited and can be equipped with a wide range of options.

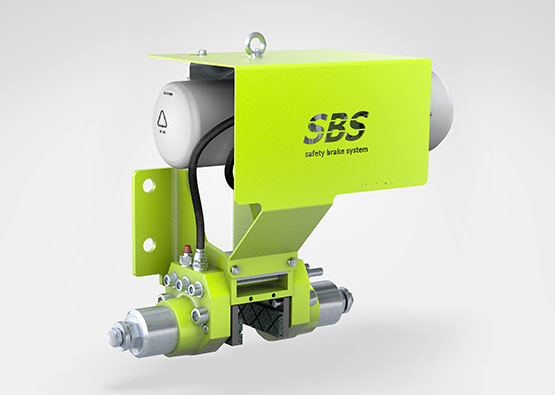

The SBS system consist of a spring applied, hydraulically released SKP model disc brake and the hydraulic brake release pressure is generated from a Hydraulic Power Pack – all incorporated on a bracket. The SBS is typically used on stacker cranes (bolted to crane structure) and the brake is acting directly on the crane travel railhead. The system communicate with the crane control system and can stop the crane wherever in the aisle in an emergency situation.

The high capacity of the SF-series makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyors.

The high capacity of the SF-series makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyor.

For many years a seawaterproof version of the SFB series has been used successfully on winch motors in ship building and as a safety, service or holding brake in wharf crane installations.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKD disc brakes are direct acting, hydraulic or air pressure applied, spring released units.

DELLNER BUBENZER's model SKDe disc brakes are direct acting electric applied, spring released units.

DELLNER BUBENZER's model SKDe disc brakes are direct acting electric applied, spring released units. The braking force achieved is directly proportional to the applied pressure.

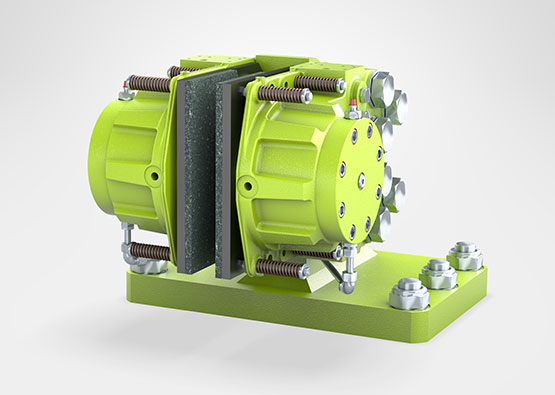

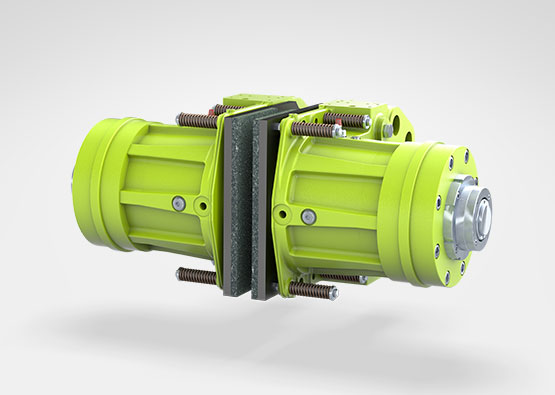

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

With a single acting (SA) brake, braking force is generated in one half of the brake and the other half slides towards it using a robust, low friction system, enabling self-alignment and making it ideal for small spaces and applications with axial movement.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.

The SKP model disc brake is a spring applied, hydraulically released brake which offers a reliable and safe of method of braking linear or rotary motion.