STL - Stop Turn Locking System

- Standard Range

- Stopping:

- Up to 285 000 Nm

- Turning:

- 227 000 Nm

- Locking:

- 600 000 Nm

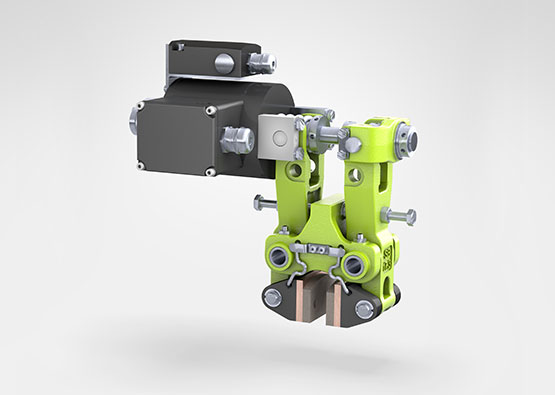

The STL Systems are "multi-function" units, all contained within one interface. It is indeed a modular system that you can choose the function(s) needed. All from single, S (Stopping) T (Turning) or L (Locking) functions. Combined dual or triple functions in terms of SL, ST, TL, to a complete STL system can be selected. Each system contain a unique control system that communicate and integrate with superior system for easy operation and control.

- Individual stopping, turning and locking functions

- Dual functions: Stop and Turn, Stop and Lock, Turn and lock

- A complete, turning and locking system

- Control systems designed and/or customized to meet platform unique integration

- Hydraulic

- Electric

- Manual

- Standard or Custom packages

- Shock and vibration approved configurations

- Hand held control units

Whether at sea or based on land, STL Systems give you complete control over your stopping, turning and locking functions.

Stopping, Turning and Locking (STL) systems are precision engineered and fully modular, making it possible to choose from the functions to create a system which fits your application:

- Individual Stopping, Turning or Locking functions

- Dual Functions:

- Stopping & Turning

- Stopping & Locking

- Turning & Locking

- Complete STL-System with all functions

- Fully automatic control

- Semi-automatic control

- Fully manual control

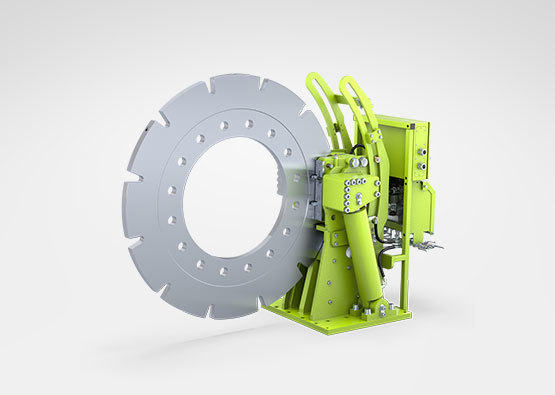

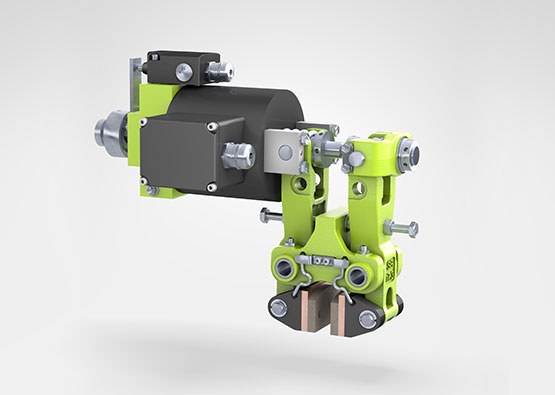

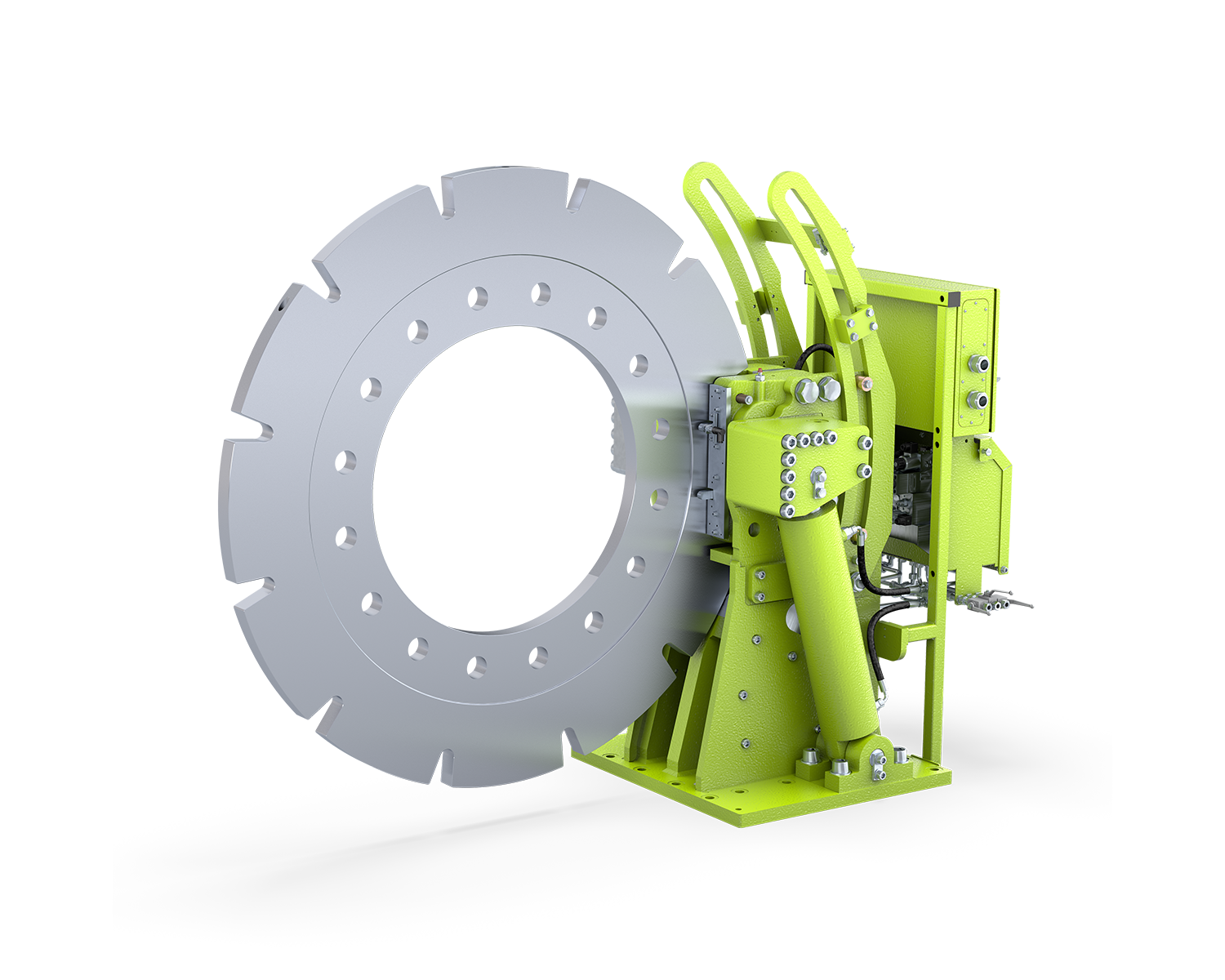

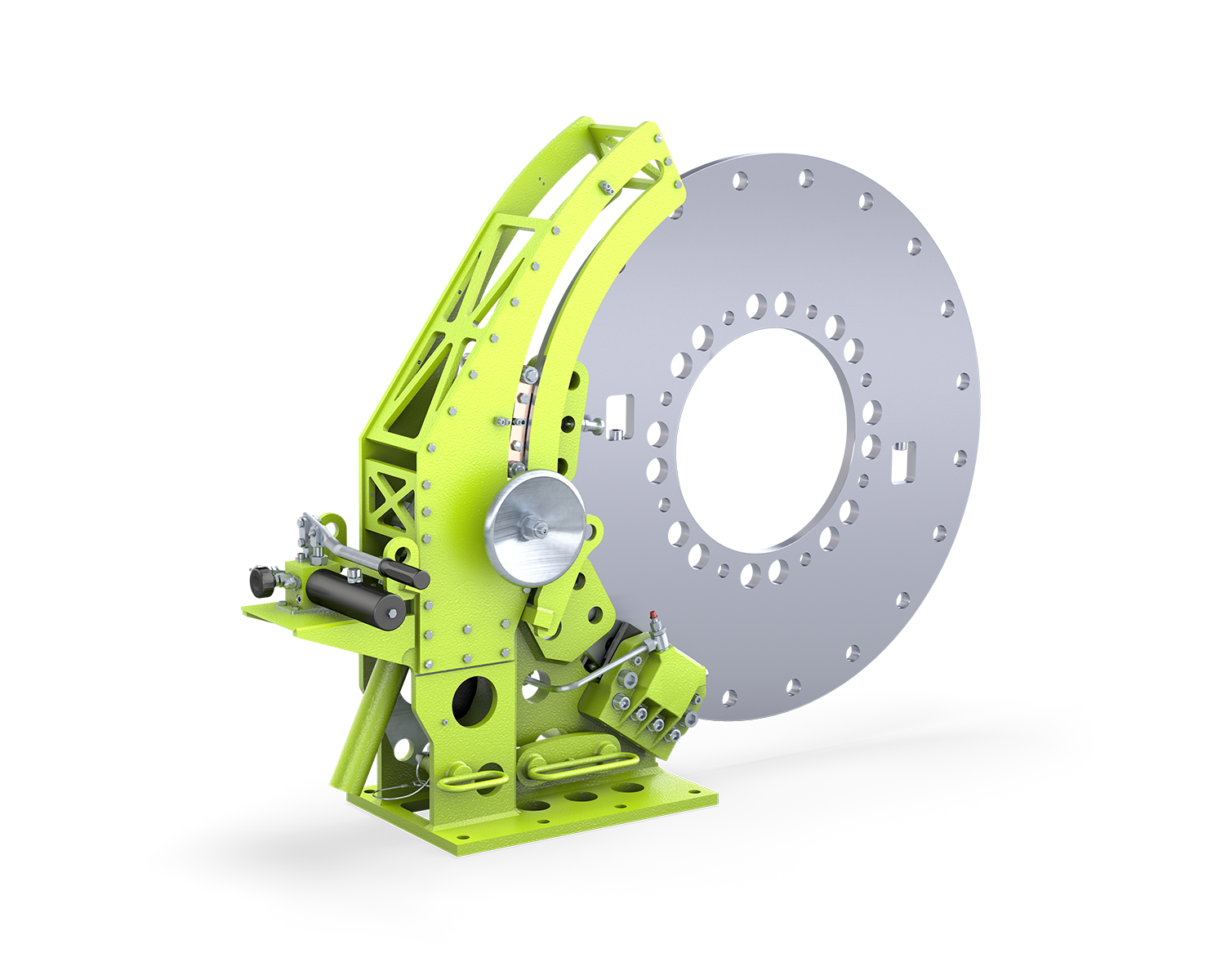

Stopping, index Turning and Locking (SiTL)

Advantages:

- Easy engagement and disengagement even with residual forces present

- Turning function is index turning with hydraulic cylinders

- Controlling can be done fully remotely, locally with push button interface, or as combination of the two controls

- Low maintenance overtime with increased personnel safety

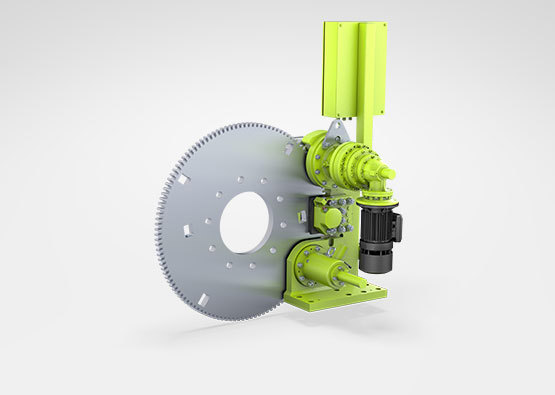

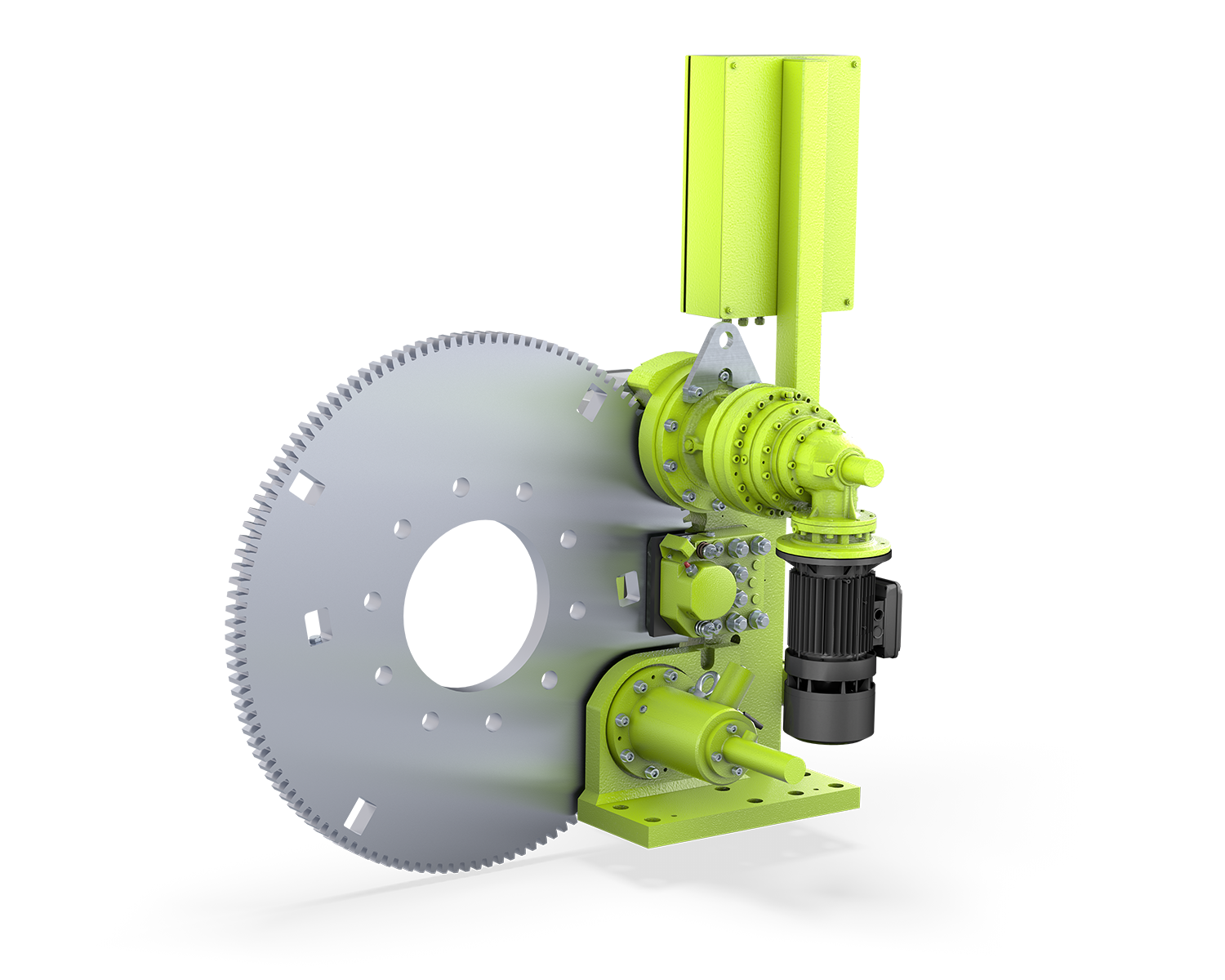

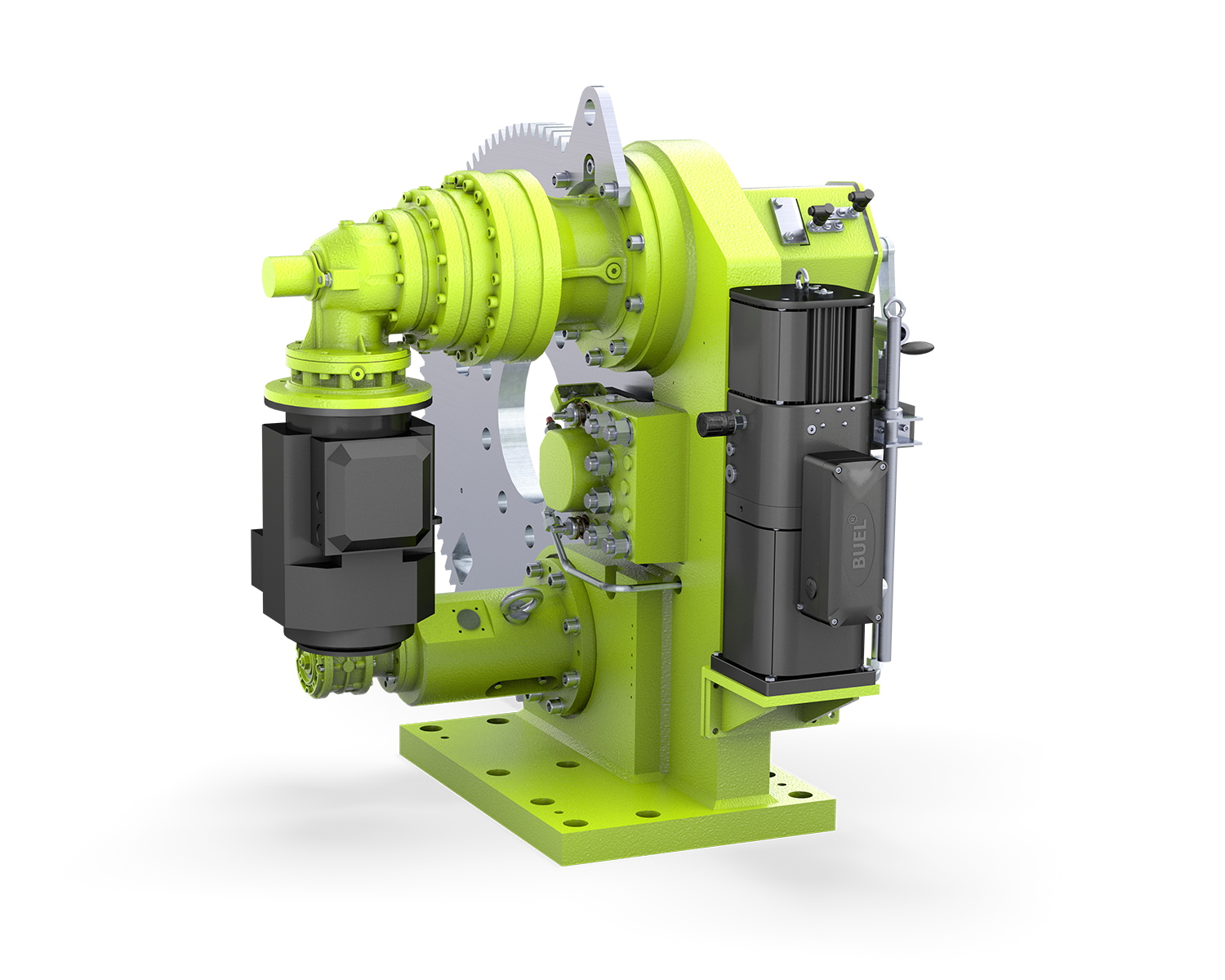

Stopping, continuous Turning and Locking (ScTL)

The electric powered continuous STL could be a preferred selection in low-range to midrange torque applications when a continuous turning operation is required and/or when manual operating has limited possibilities.

Advantages:

- Easy engagement and disengagement even with residual forces present

- Turning function is continuous turning with electric motor and gearbox

- Controlling can be done fully remotely, locally with push button interface, or as combination of the two controls

- Low maintenance overtime with increased personnel safety

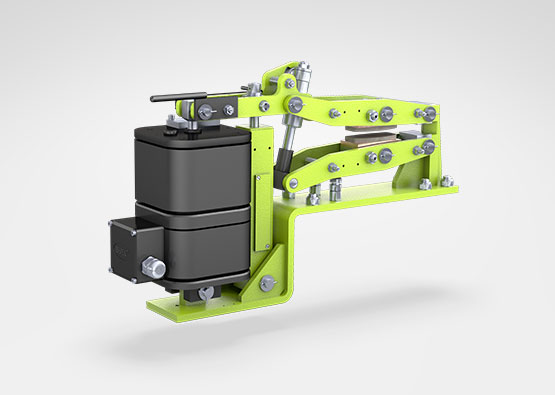

Stopping, continuous Turning and Locking (ScTL) with BUEL®

DELLNER BUBENZER’s compact, self contained BUEL® STL systems combine elements from STL with DELLNER BUBENZER’s patented BUEL® electrohydraulic thruster/power package.

Needing no external piping, the systems are compact, easy to install, and with the BUEL® using only half a litre of high performance synthetic oil (compared to up to 30 litres of hydraulic oil in standard hydraulic power units), are cheaper to run and enviromentally-friendly too.

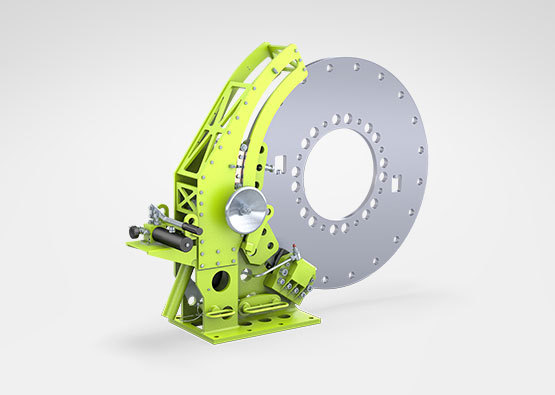

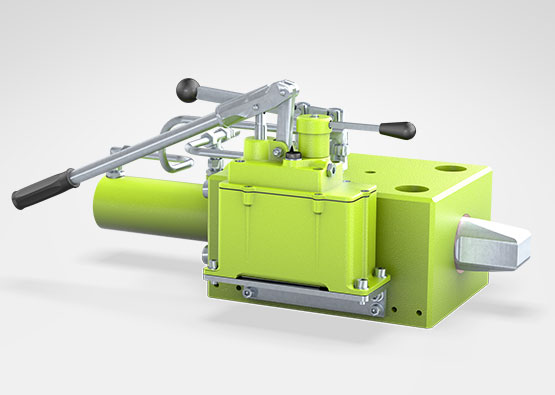

Fully Manual Stopping, index Turning and Locking (SiTL)

The electric powered continuous STL could be a preferred selection in low-range to midrange torque applications when a continuous turning operation is required and/or when manual operating has limited possibilities.

Advantages:

- Easy engagement and disengagement even with residual forces present

- Turning function is indexed turning with fully manual control

- Controlling is done fully locally, with provision for instruments for status detection (interlock)

- Fully independent from external power sources

- Low maintenance overtime with increased personnel safety

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

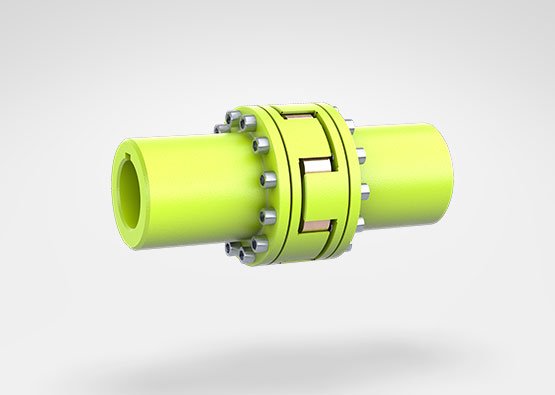

The KBSD Gear Couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

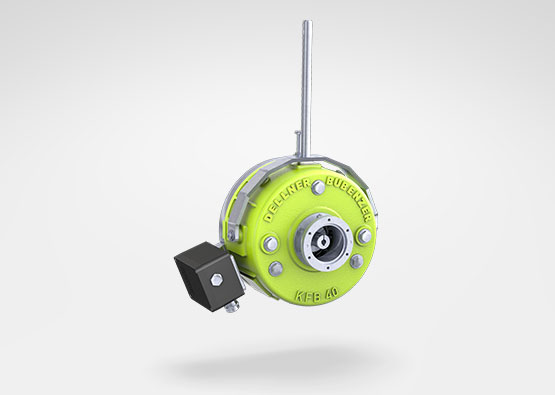

The KFB is a spring applied safety brake which is mainly used in gantry, trolley and hoisting application on harbour crane systems, in dynamic and static use at general industrial applications, in mechanical engineering, steel mills, coal mining or wind energy systems.

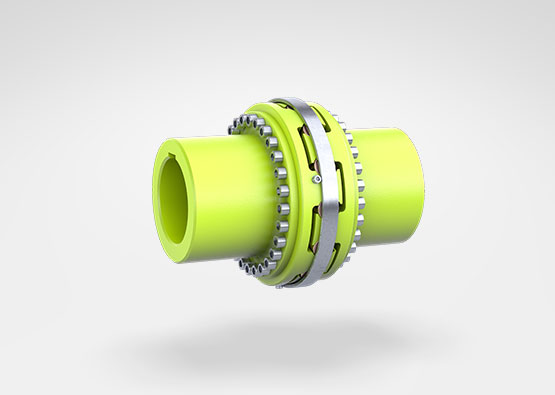

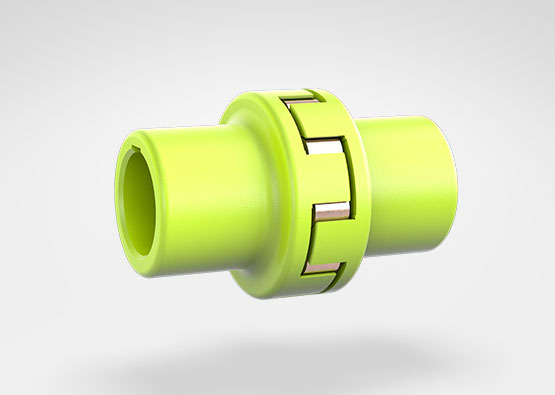

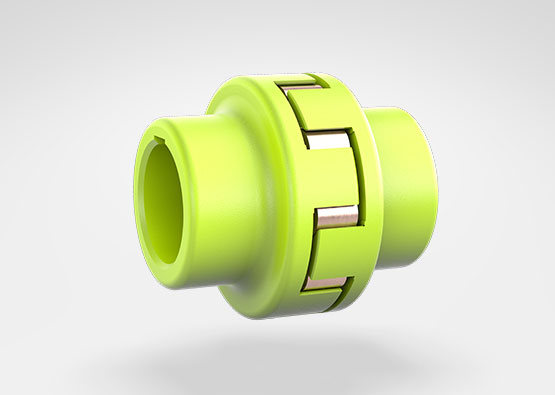

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

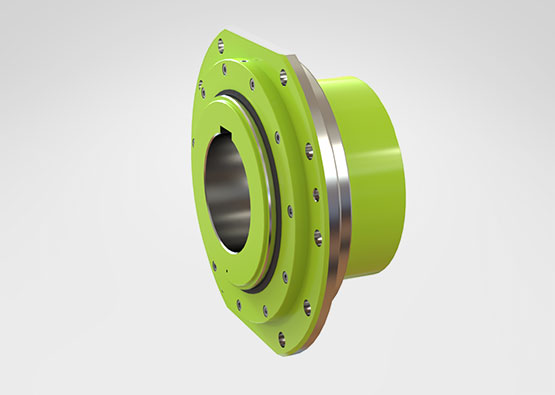

Models within LM series (locking devices) are fail safe and used to mechanically lock a rotational or linear application in a controlled position.

Models within LM sere (locking devices) are fail safe and used to mechanically lock a rotational or linear application in a controlled position.

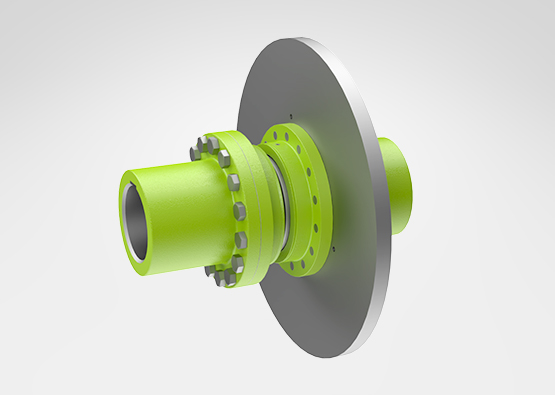

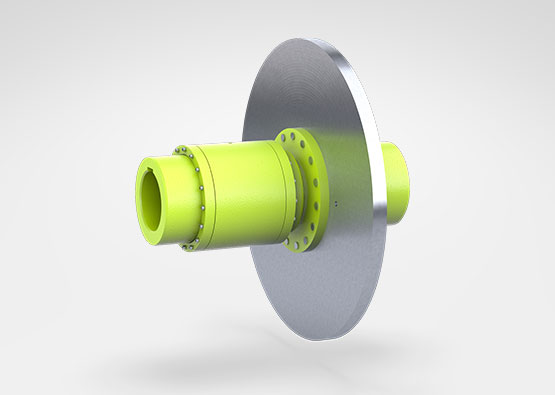

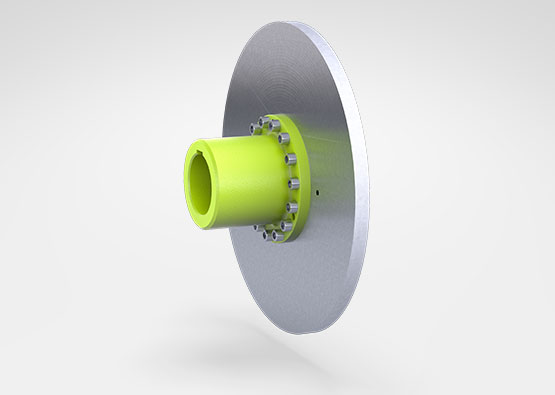

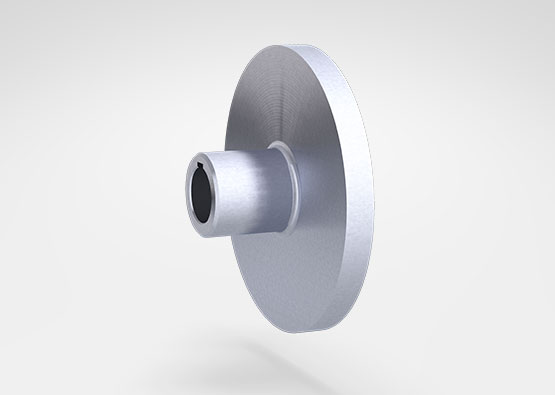

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

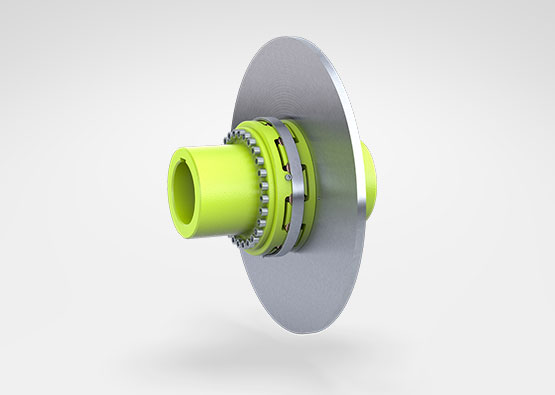

The NTRST Drum Couplings is a high-performance solution for hoist, winches, and conveying systems, ensuring a reliable connection between the gearbox output shaft and the rope drum. Designed to compensate for misalignments caused by bending drum structures, it enhances equipment lifespan and reduces wear.

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

The SB 16 brake has a very compact design and is often used on trolleys for container gantry cranes, RTG and RMG equipment

The SB 17.3 MX brake is a spring-actuated, magnetic-return disc brake for trolley applications on container gantry cranes and other port logistics equipment. Furthermore, the very compact design results in a range of industrial applications in various industries

The SB series stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 22 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 23.3 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.