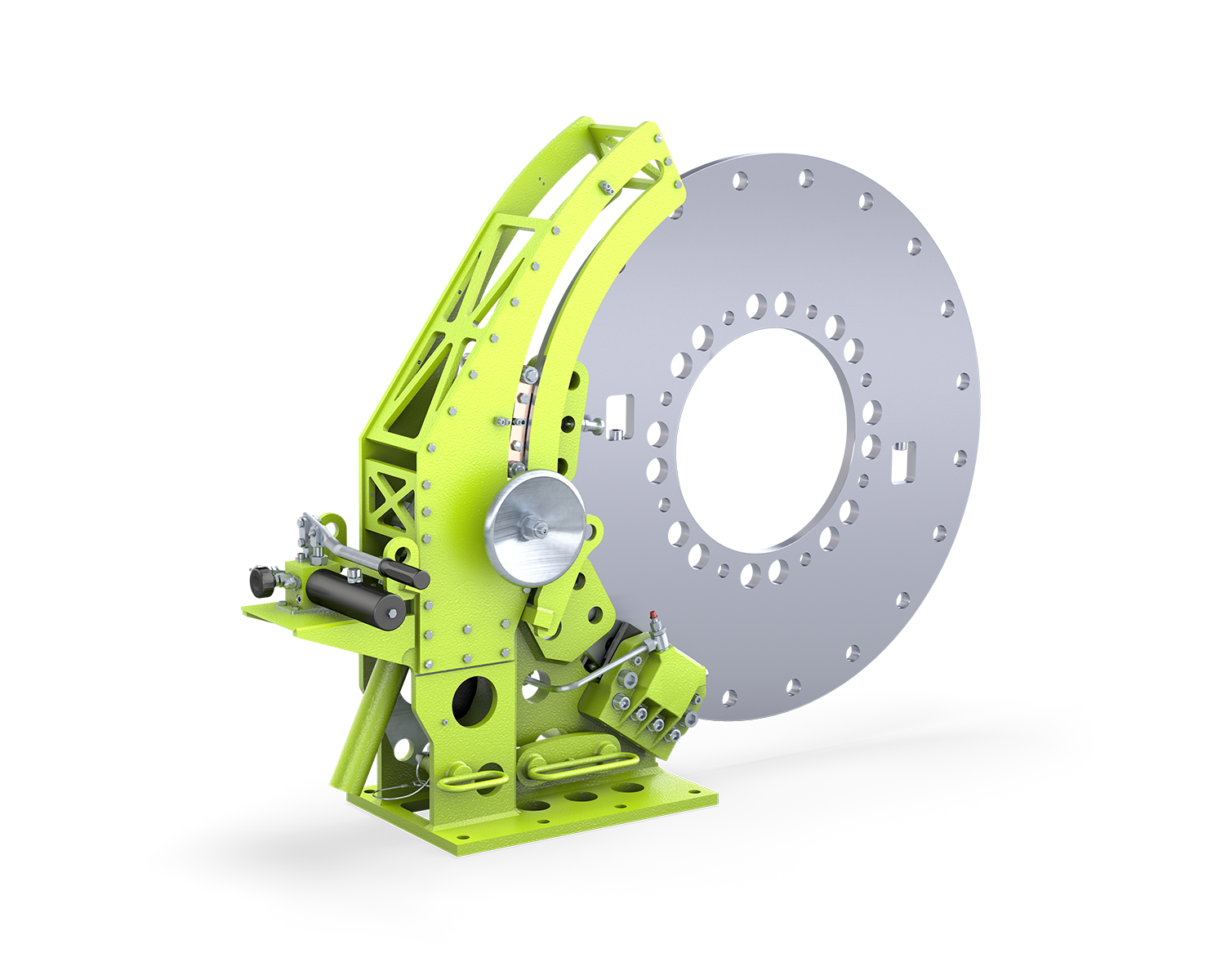

STL - Stop Turn Locking System

- Standard Range

- Stopping:

- Up to 285 000 Nm

- Turning:

- 227 000 Nm

- Locking:

- 600 000 Nm

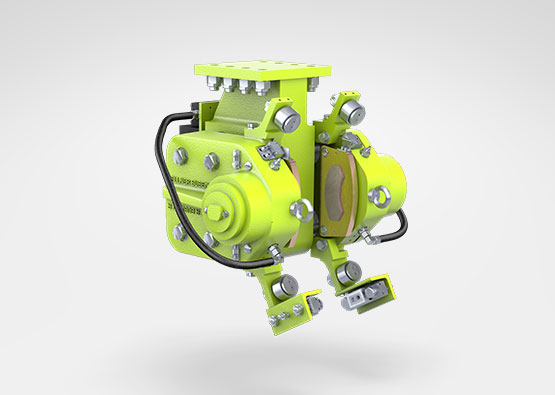

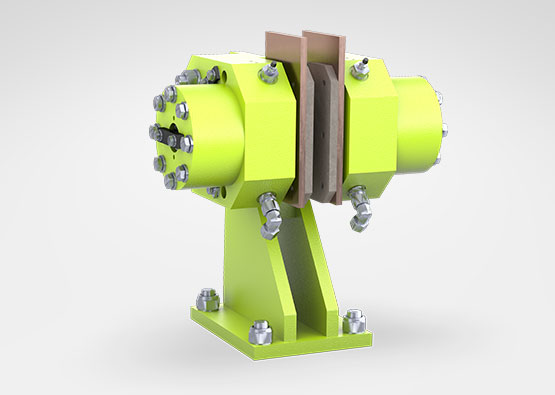

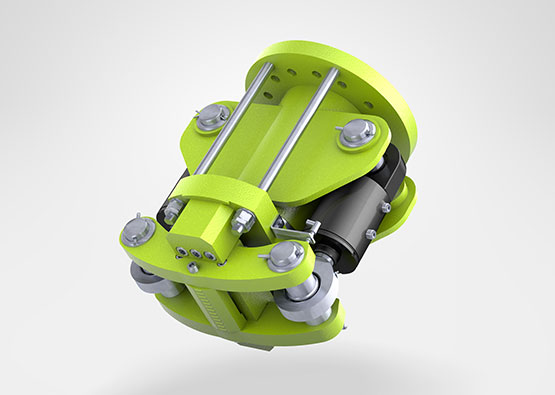

The STL Systems are "multi-function" units, all contained within one interface. It is indeed a modular system that you can choose the function(s) needed. All from single, S (Stopping) T (Turning) or L (Locking) functions. Combined dual or triple functions in terms of SL, ST, TL, to a complete STL system can be selected. Each system contain a unique control system that communicate and integrate with superior system for easy operation and control.

- Individual stopping, turning and locking functions

- Dual functions: Stop and Turn, Stop and Lock, Turn and lock

- A complete, turning and locking system

- Control systems designed and/or customized to meet platform unique integration

- Hydraulic

- Electric

- Manual

- Standard or Custom packages

- Shock and vibration approved configurations

- Hand held control units

Whether at sea or based on land, STL Systems give you complete control over your stopping, turning and locking functions.

Stopping, Turning and Locking (STL) systems are precision engineered and fully modular, making it possible to choose from the functions to create a system which fits your application:

- Individual Stopping, Turning or Locking functions

- Dual Functions:

- Stopping & Turning

- Stopping & Locking

- Turning & Locking

- Complete STL-System with all functions

- Fully automatic control

- Semi-automatic control

- Fully manual control

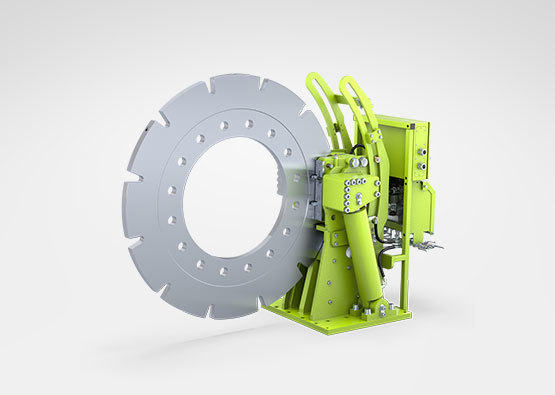

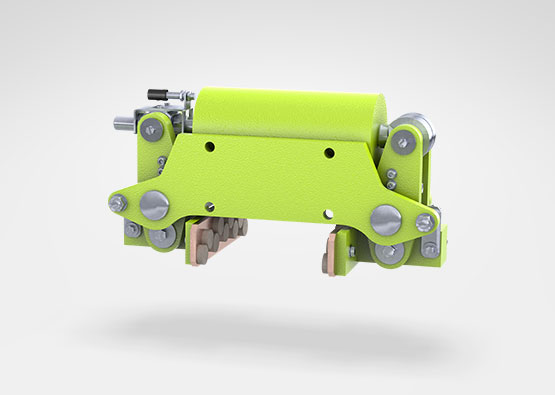

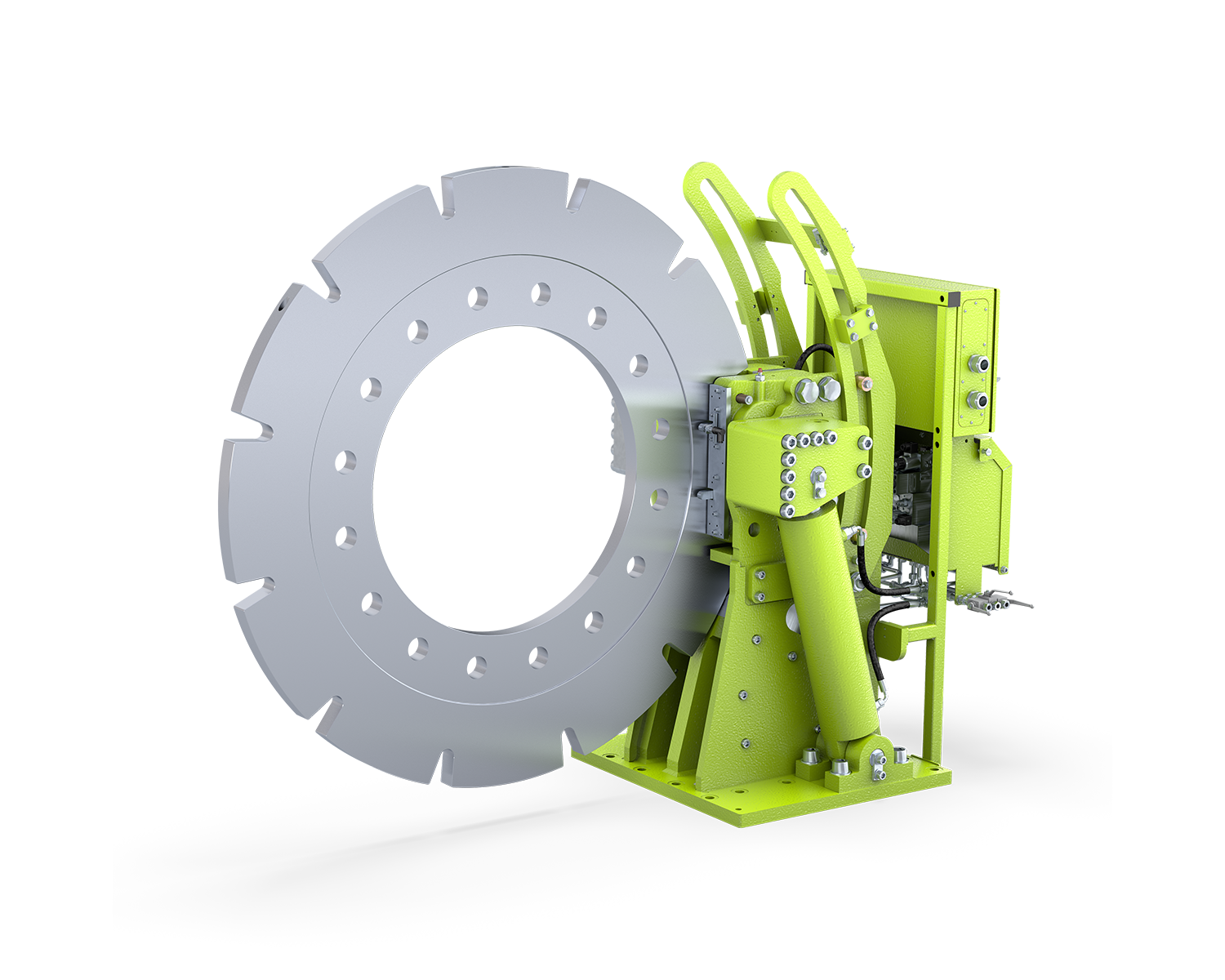

Stopping, index Turning and Locking (SiTL)

Advantages:

- Easy engagement and disengagement even with residual forces present

- Turning function is index turning with hydraulic cylinders

- Controlling can be done fully remotely, locally with push button interface, or as combination of the two controls

- Low maintenance overtime with increased personnel safety

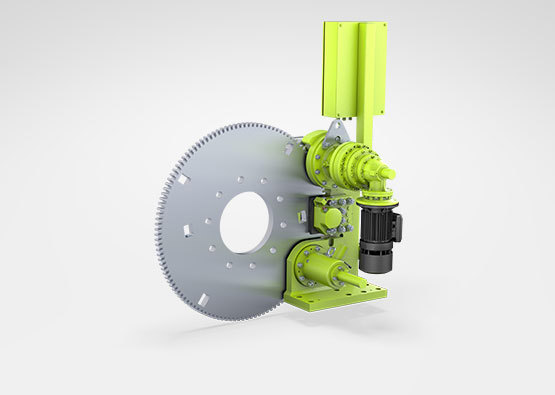

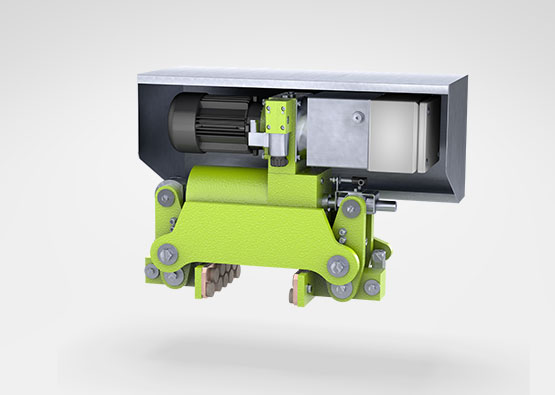

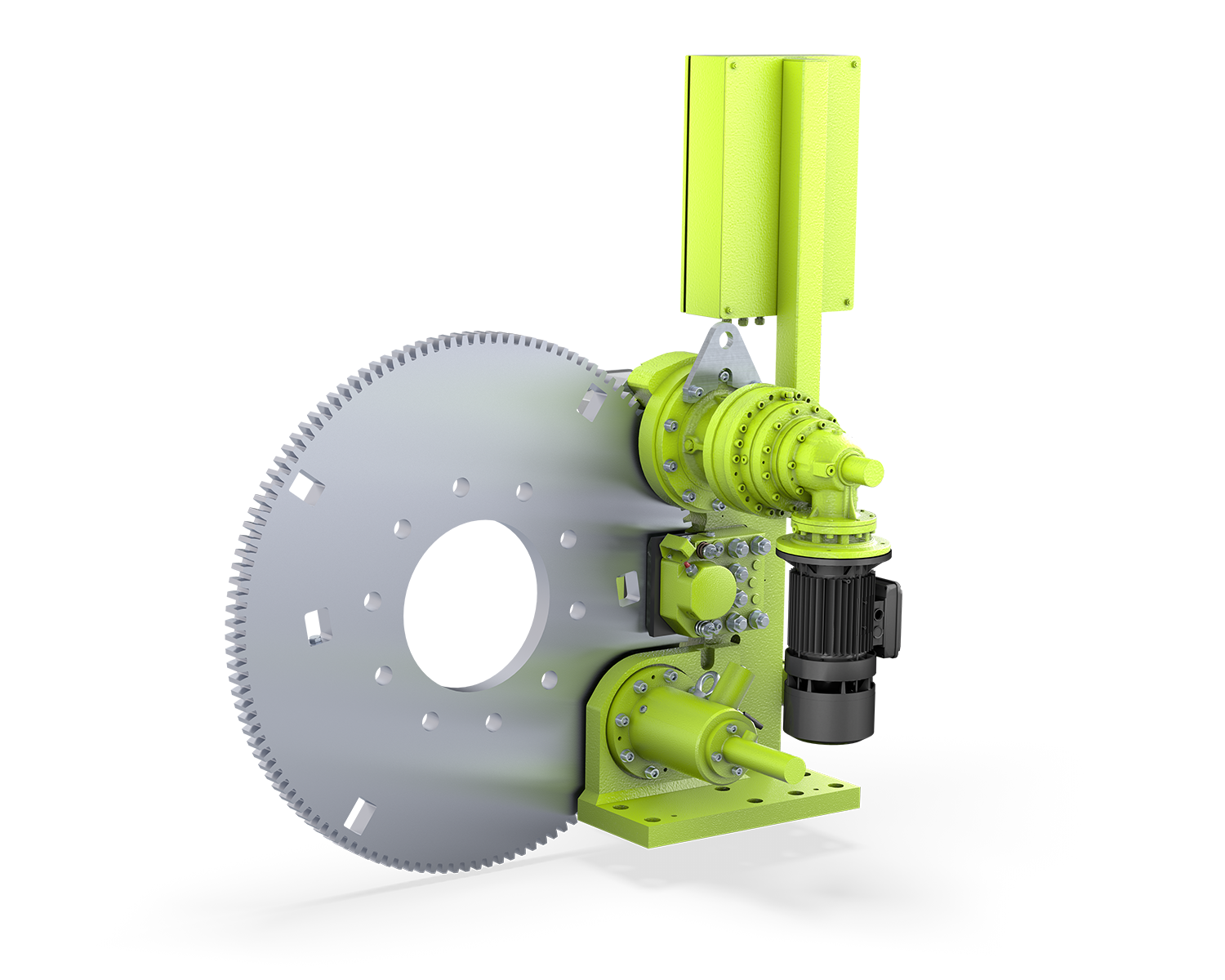

Stopping, continuous Turning and Locking (ScTL)

The electric powered continuous STL could be a preferred selection in low-range to midrange torque applications when a continuous turning operation is required and/or when manual operating has limited possibilities.

Advantages:

- Easy engagement and disengagement even with residual forces present

- Turning function is continuous turning with electric motor and gearbox

- Controlling can be done fully remotely, locally with push button interface, or as combination of the two controls

- Low maintenance overtime with increased personnel safety

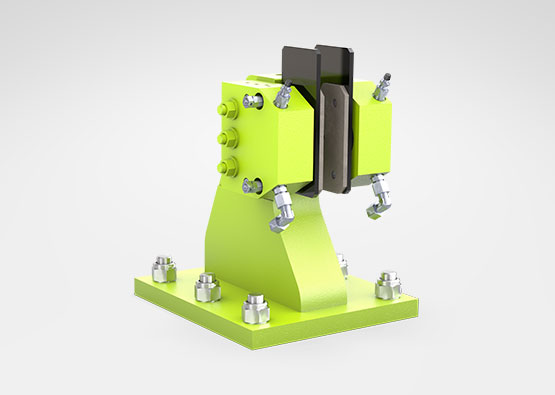

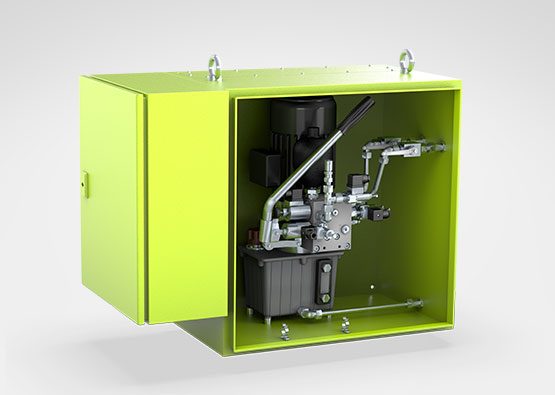

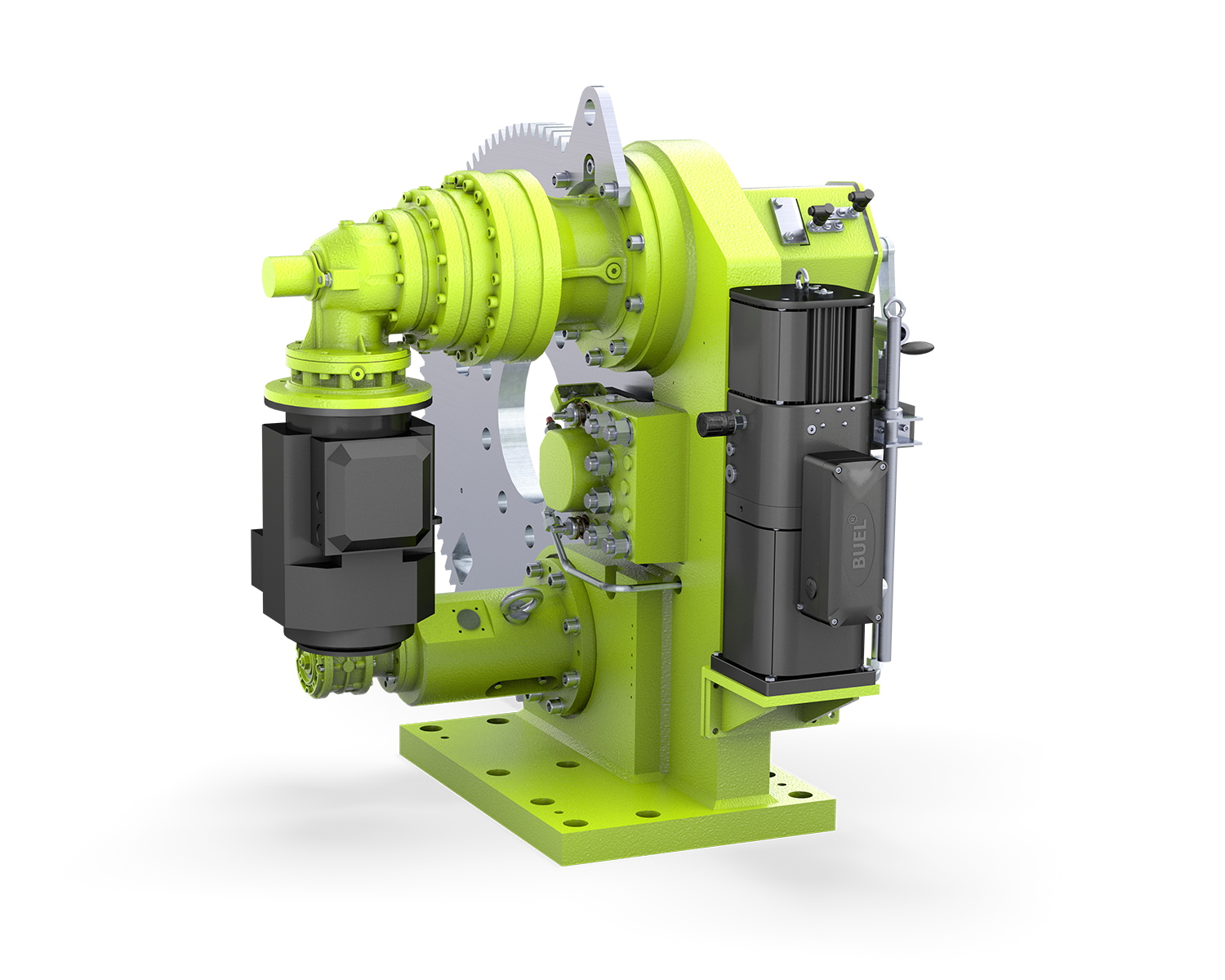

Stopping, continuous Turning and Locking (ScTL) with BUEL®

DELLNER BUBENZER’s compact, self contained BUEL® STL systems combine elements from STL with DELLNER BUBENZER’s patented BUEL® electrohydraulic thruster/power package.

Needing no external piping, the systems are compact, easy to install, and with the BUEL® using only half a litre of high performance synthetic oil (compared to up to 30 litres of hydraulic oil in standard hydraulic power units), are cheaper to run and enviromentally-friendly too.

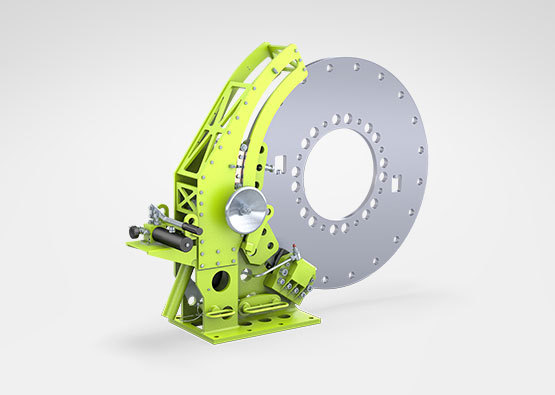

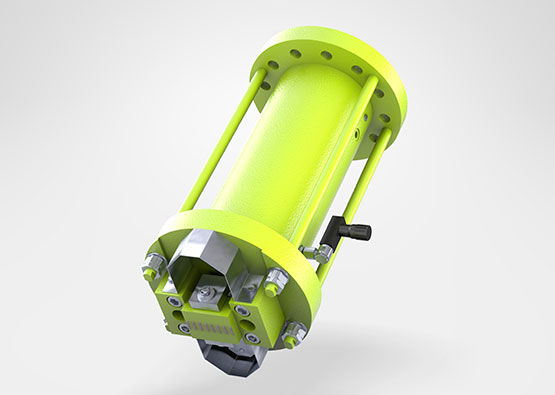

Fully Manual Stopping, index Turning and Locking (SiTL)

The electric powered continuous STL could be a preferred selection in low-range to midrange torque applications when a continuous turning operation is required and/or when manual operating has limited possibilities.

Advantages:

- Easy engagement and disengagement even with residual forces present

- Turning function is indexed turning with fully manual control

- Controlling is done fully locally, with provision for instruments for status detection (interlock)

- Fully independent from external power sources

- Low maintenance overtime with increased personnel safety

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

DELLNER BUBENZER's Anti Sway Systems allow the damping of head-block, spreader and container oscillation generated by acceleration / deceleration of trolley and gantry.

The BAC-brakes is used for stopping and/or holding of fans, blowers, wind turbines, coilers, crane slewing and travel gears etc.

Band Brake for large torque applications that can be used for emergencies or back up braking needs. Band Brakes have been around for many years and we offer many ways to operate via thruster, air, hydraulic or hand wheel.

The BOSS® Brake Only Snag System system has been developed based on the experience with the SOS system that has been already installed in more than 200 container cranes world wide.

The BCMS-4 is a micro-controller-based monitoring and switching device for spring applied brakes of the SFB and KFB series.

The Brake Control Unit BCU 2001 records characteristic current and voltage variations, which are induced by movements of the armature disk in the magnetic field of the brake coil.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane. They are hydraulic powered with HPU or BUEL® G.

The high capacity of these brakes makes them particularly suitable as service- or secondary emergency brakes e.g. on hoists, slewing drives and belt conveyors.

The BUEL® Model G is a new family member of the DELLNER BUBENZER brand BUEL®. It is a compact thruster to feed active or passive hydraulic brakes and emergency brakes.

The BUEL® Model H is a family member of the DELLNER BUBENZER brand BUEL®. BUEL® thrusters are used for almost all kind of industrial applications.

Compact status monitoring system for a brake system with display and fieldbus interface.

Compact status monitoring system for a brake system with display and fieldbus interface.

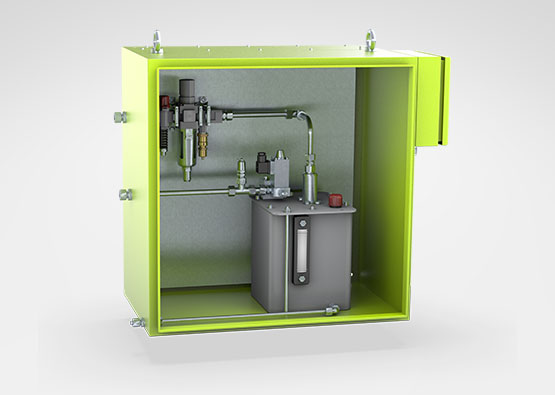

Compactus is a pneumatically operated hydraulic pump system that multiplies pneumatic line pressure into hydraulic pressure that is sufficient to operate pressure applied disc brakes at rated capacity.

The DB hydraulic power packs deliver pressure up to 200 bar and can be delivered with optional hydraulic cabinets and electrical terminal boxes.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane.

DELLNER BUBENZER's DBSB is a storm safety brake for all rail mounted equipment, e. g. cranes, stackers, reclaimers etc.

Rail brakes work pressing down on the top of rail by disk springs. Brakes are hydraulically released. Usual parking utilisation requires a few closing / opening cycles per day.