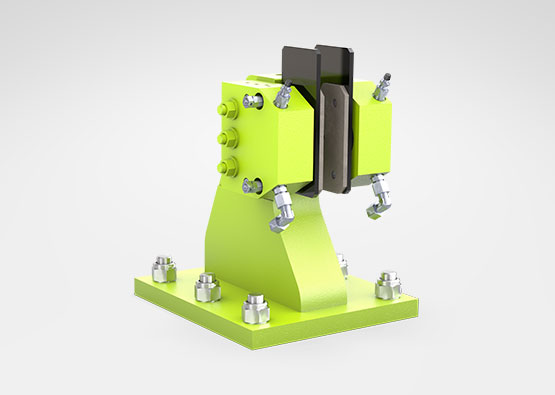

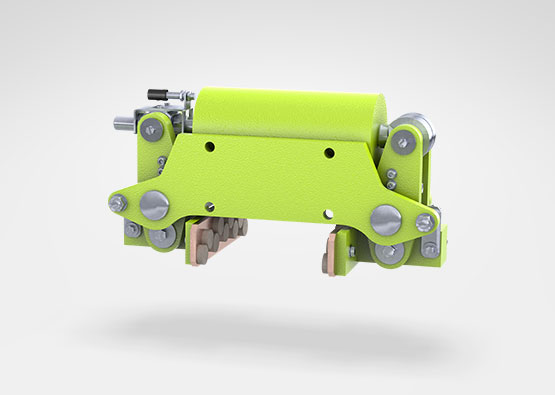

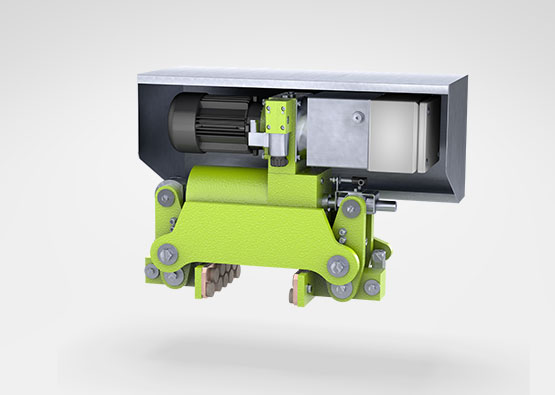

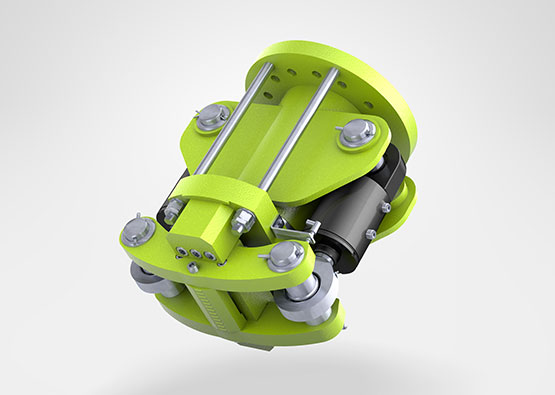

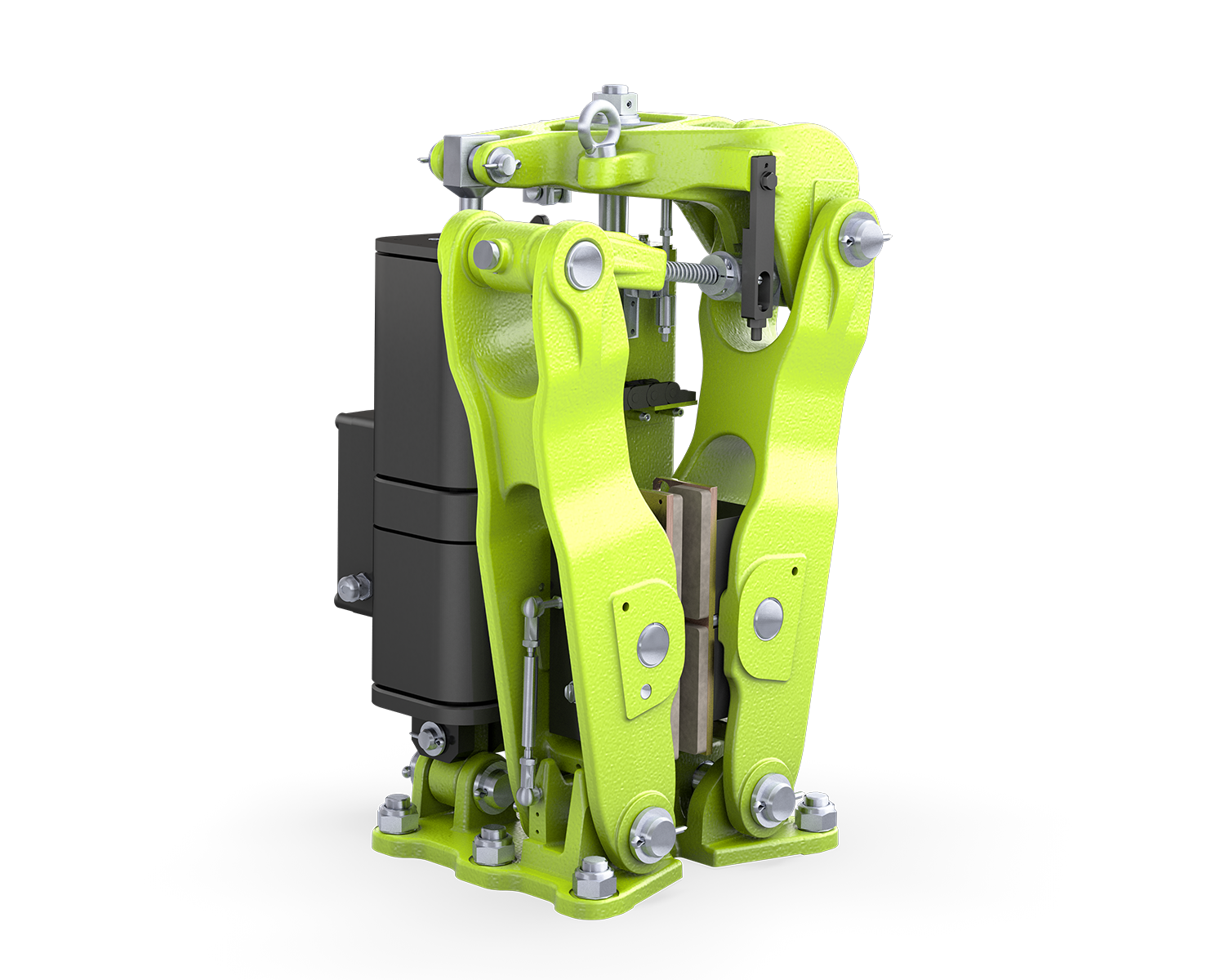

SB 28.5

- Torque:

- 23400 Nm

- Contact Force:

- 65000 N

To uphold our reputation as a global leader in braking systems and manufacturing solutions, the SB 28.5 represents DELLNER BUBENZER’s commitment to constantly innovate, provide industry solutions and anticipate the needs of our customers. Supported by decades of engineering, evolution, and innovation, the SB28.5 brake presents significant advantages with an enhanced and compact design, sustainability, and preeminent performance. Welcome to the SB 28.5, the new generation of SB-disc brake series.

- Proximity switch brake release

- Manual release lever with or without lock

- Manual release lever latching or non latching

- Automatic wear compensator

- Sintered linings for high friction speeds

- Continuously adjustable brake spring with torque scale and wear bushing enclosed in a spring tube

- Stainless steel pins and spindles

- W-execution (special anti-corrosion protection)

- Maintenance-free bushings in all hinge points

- Symmetric design

- Parallel air gap when brake is released (no tipping of the brake shoes)

- Proximity switch pad wear

- Proximity switch hand release

- Monitoring systems (e.g. VSR/CMB)

- Brake disc with hub or coupling

- Option: Terminal box for limit switches

- Special painting for increased corrosion protection

- Manual release lever on top of BUEL® thruster

SB 28.5 FEATURES

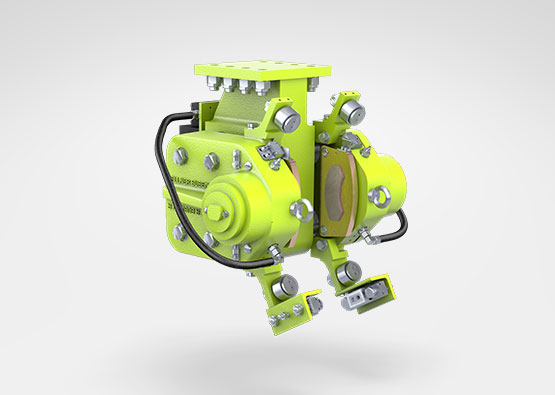

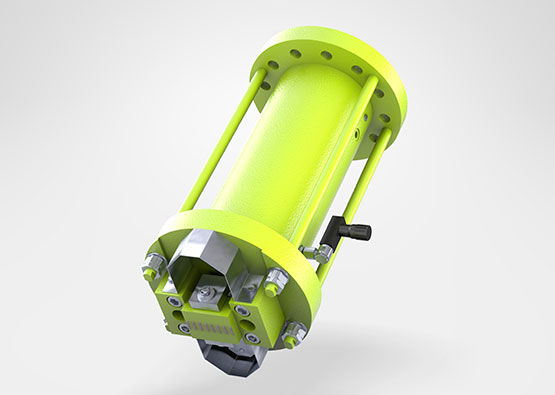

Sustainability

Developed on the foundation of decades of experience in power transmission, BUEL® sets the industry standard for reliability, safety, and environmental impact.

- BUEL® Thruster & Reduced Energy Costs

- Reduced Fluid Volume

- Eco-friendly Biodegradable Oil

SB 28.5 FEATURES

Enhanced Design

Supported by decades of engineering, the SB 28.5 brake presents significant advantages with preeminent performance and sustainability.

- Facelift, Weight Savings & Reduced Carbon Footprint

- 101 Interchangeability

- Easy Installation & Commissioning

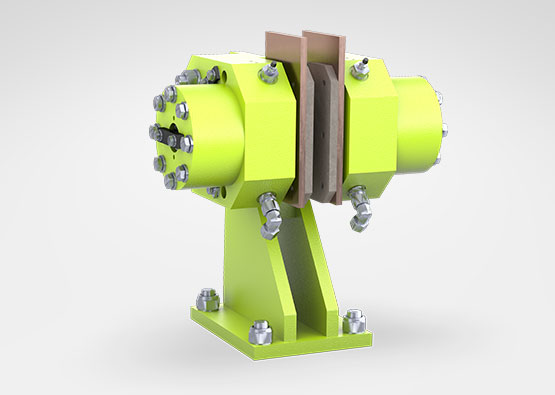

SB 28.5 FEATURES

Automated Wear Compensation

Upgrading our products for optimal performance potential, expands and enhances our product portfolio with precision and expertise.

- Freewheel-based Automatic Wear Compensator

- Easy Maintenance

SB 28.5 FEATURES

Improved Self-Centering System

To uphold our reputation as a global leader, we deploy the latest in technology and mirror what the market needs, and our clients deserve.

- New & Upgraded System by Roller & Cam

- Equal Air Gaps with Self-centering Brake Levers

SB 28.5 FEATURES

Enhanced Parallel Alignment System

- Symmetric Designed Brakes

- Brakes Shoes are Parallel Positioned to the Brake Disc

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

DELLNER BUBENZER's Anti Sway Systems allow the damping of head-block, spreader and container oscillation generated by acceleration / deceleration of trolley and gantry.

The BAC-brakes is used for stopping and/or holding of fans, blowers, wind turbines, coilers, crane slewing and travel gears etc.

Band Brake for large torque applications that can be used for emergencies or back up braking needs. Band Brakes have been around for many years and we offer many ways to operate via thruster, air, hydraulic or hand wheel.

The BOSS® Brake Only Snag System system has been developed based on the experience with the SOS system that has been already installed in more than 200 container cranes world wide.

The BCMS-4 is a micro-controller-based monitoring and switching device for spring applied brakes of the SFB and KFB series.

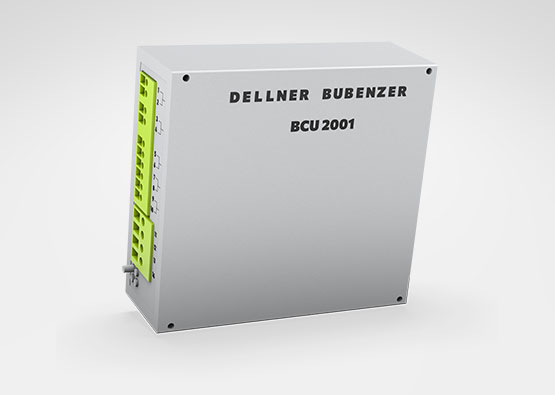

The Brake Control Unit BCU 2001 records characteristic current and voltage variations, which are induced by movements of the armature disk in the magnetic field of the brake coil.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane. They are hydraulic powered with HPU or BUEL® G.

The high capacity of these brakes makes them particularly suitable as service- or secondary emergency brakes e.g. on hoists, slewing drives and belt conveyors.

The BUEL® Model G is a new family member of the DELLNER BUBENZER brand BUEL®. It is a compact thruster to feed active or passive hydraulic brakes and emergency brakes.

The BUEL® Model H is a family member of the DELLNER BUBENZER brand BUEL®. BUEL® thrusters are used for almost all kind of industrial applications.

Compact status monitoring system for a brake system with display and fieldbus interface.

Compact status monitoring system for a brake system with display and fieldbus interface.

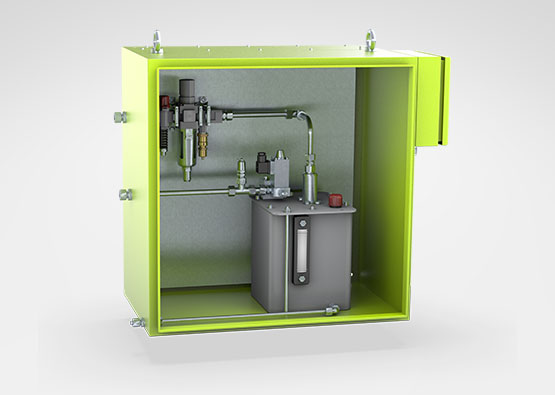

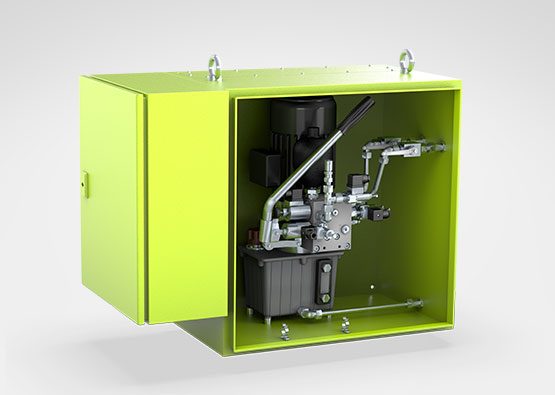

Compactus is a pneumatically operated hydraulic pump system that multiplies pneumatic line pressure into hydraulic pressure that is sufficient to operate pressure applied disc brakes at rated capacity.

The DB hydraulic power packs deliver pressure up to 200 bar and can be delivered with optional hydraulic cabinets and electrical terminal boxes.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane.

These brakes are for parking utilization, securing the crane against the wind force. In emergency condition they can be operated also as dynamic brakes to stop the crane.

DELLNER BUBENZER's DBSB is a storm safety brake for all rail mounted equipment, e. g. cranes, stackers, reclaimers etc.

Rail brakes work pressing down on the top of rail by disk springs. Brakes are hydraulically released. Usual parking utilisation requires a few closing / opening cycles per day.