EBN

- Torque:

- 6920 Nm

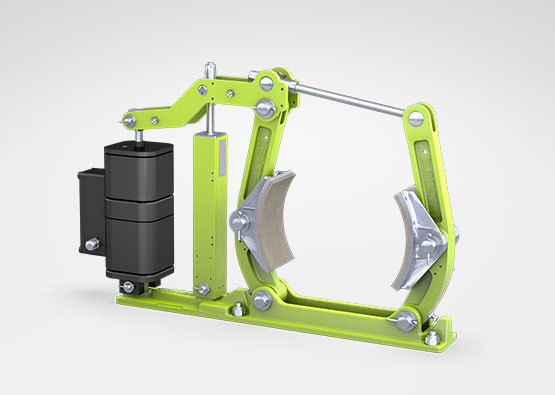

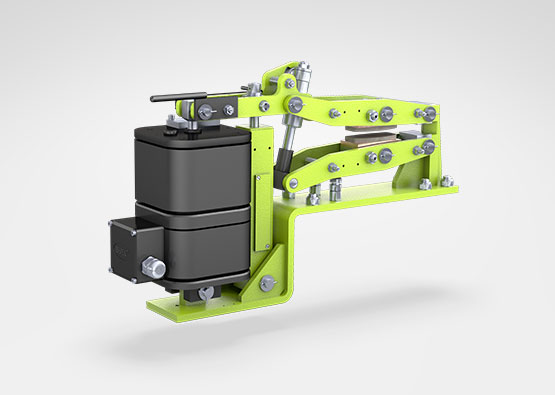

The EBN is a powerful drum brake with automatic wear adjustment and braking torques from 325 to 6920 Nm.

EBN-2St modification: the ideal solution for Bridges and Sluice Systems

- According to DIN 15435 standard

- Continuously adjustable brake spring enclosed in a square tube with torque scale

- Self-lubricating bushings mean brakes are easy to service, no greasing necessary

- Equal air gap by adjustable lever stops

- Up to size 400:

- Levers and base plate made of nodular cast iron

- From size 500:

- Levers and base plate made of welded steel

- Different thrusters

- Aluminum brake shoes acc. DIN 15435 Bl. 2 with non-asbestos, organic linings

- Shoe clamping springs which prevent brake shoes from tilting when released

- Pins and main spindle of stainless steel

- Uncoated parts and screws of stainless steel

- Automatic wear compensator

- Proximity switch release control

- Proximity switch pad wear

- Proximity switch hand release

- Manual release lever with or w/o interlock

- Monitoring systems (e.g. VSR/CMB)

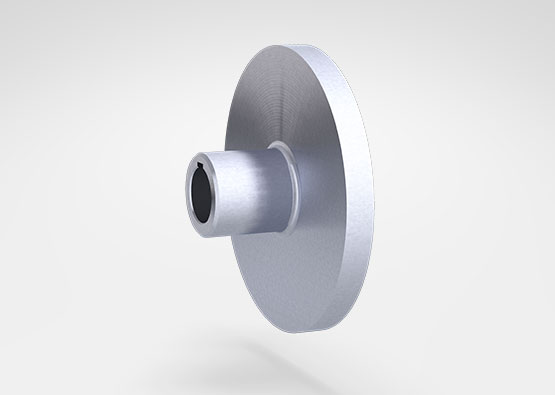

- Brake drums with hubs or couplings

- Weather execution (special paint and coating) for outdoor use

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

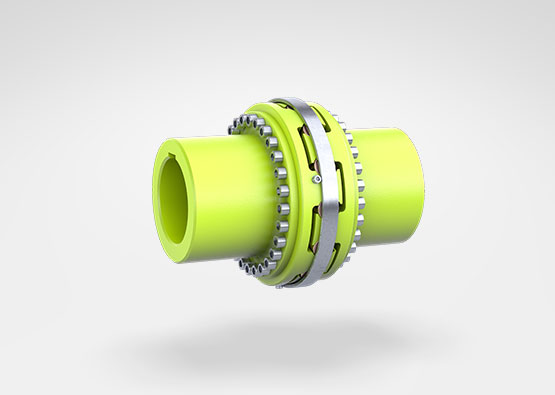

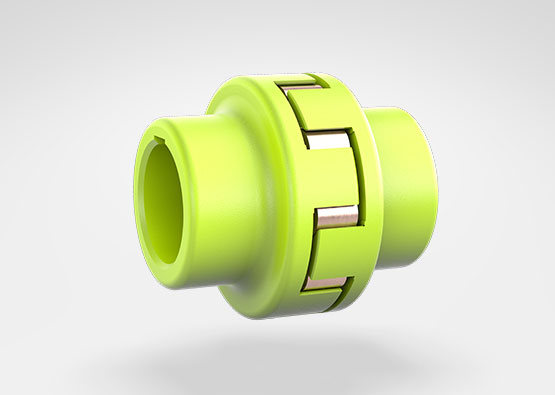

The KBSD Gear Couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

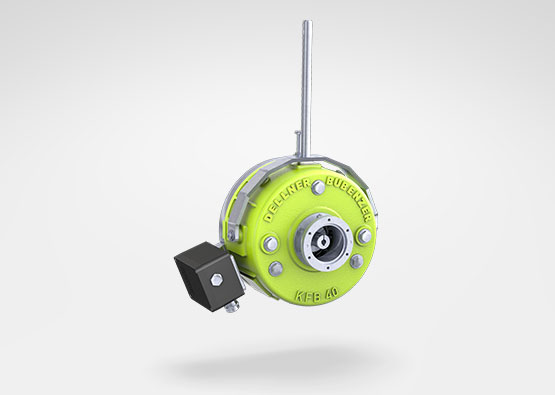

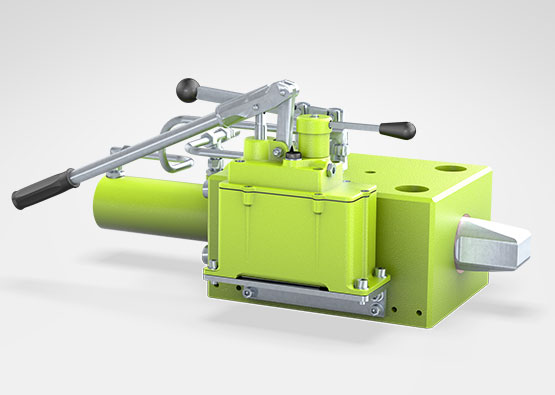

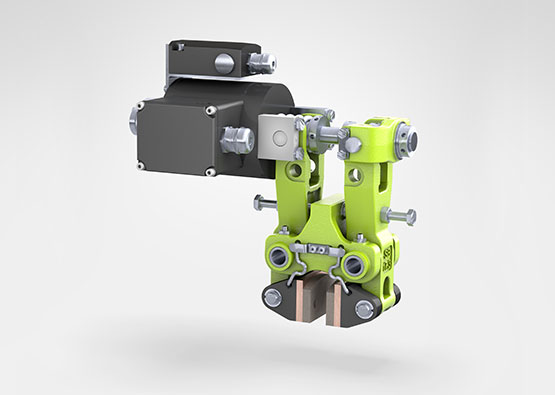

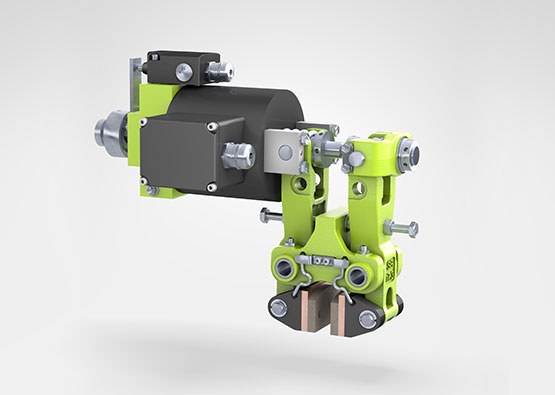

The KFB is a spring applied safety brake which is mainly used in gantry, trolley and hoisting application on harbour crane systems, in dynamic and static use at general industrial applications, in mechanical engineering, steel mills, coal mining or wind energy systems.

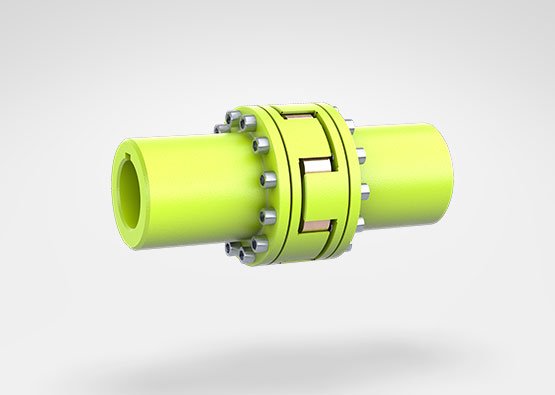

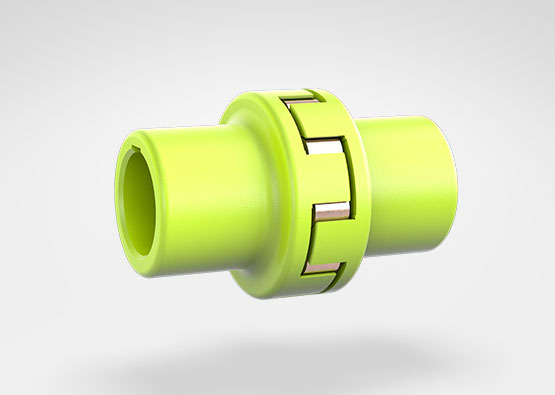

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

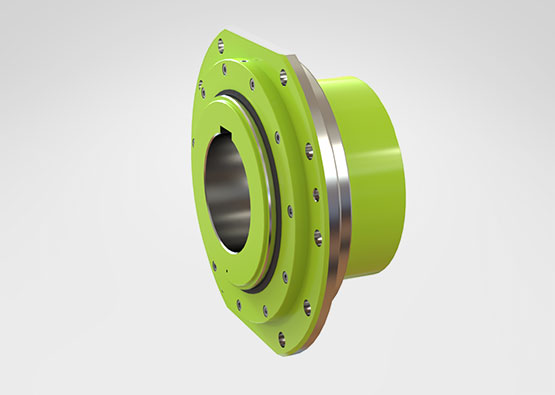

Models within LM series (locking devices) are fail safe and used to mechanically lock a rotational or linear application in a controlled position.

Models within LM sere (locking devices) are fail safe and used to mechanically lock a rotational or linear application in a controlled position.

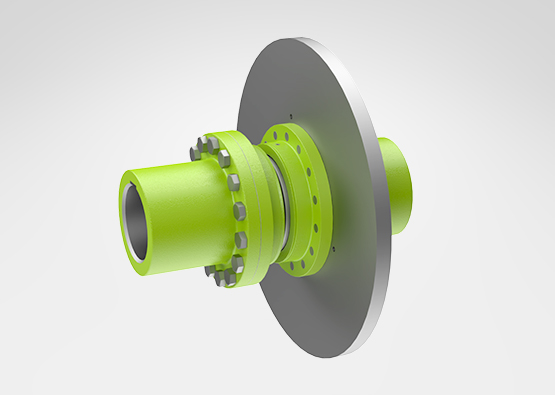

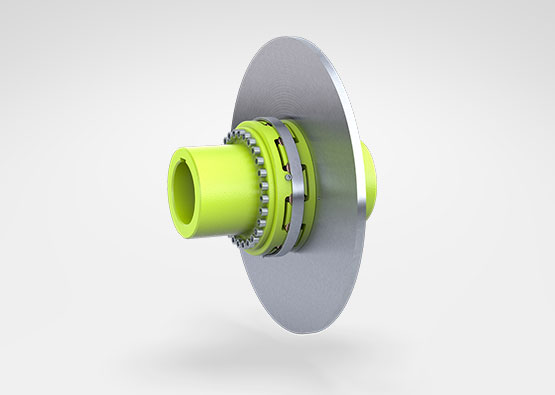

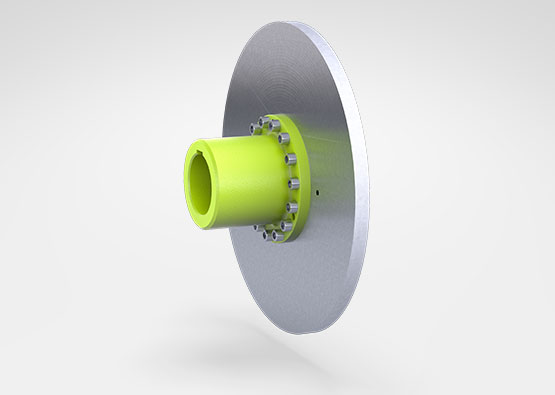

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

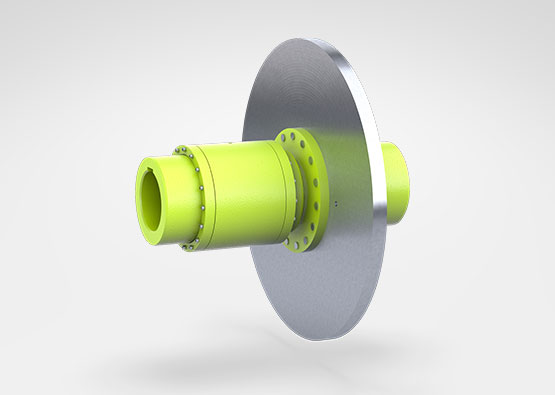

The NTRST Drum Couplings is a high-performance solution for hoist, winches, and conveying systems, ensuring a reliable connection between the gearbox output shaft and the rope drum. Designed to compensate for misalignments caused by bending drum structures, it enhances equipment lifespan and reduces wear.

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

The SB 16 brake has a very compact design and is often used on trolleys for container gantry cranes, RTG and RMG equipment

The SB 17.3 MX brake is a spring-actuated, magnetic-return disc brake for trolley applications on container gantry cranes and other port logistics equipment. Furthermore, the very compact design results in a range of industrial applications in various industries

The SB series stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 22 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 23.3 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.