DBSZ

- Holding Force:

- Up to 800 kN (higher force on request)

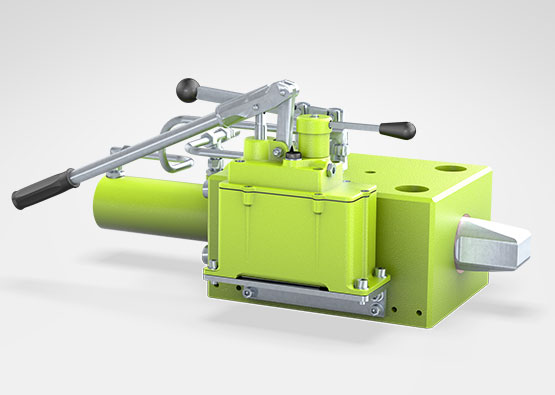

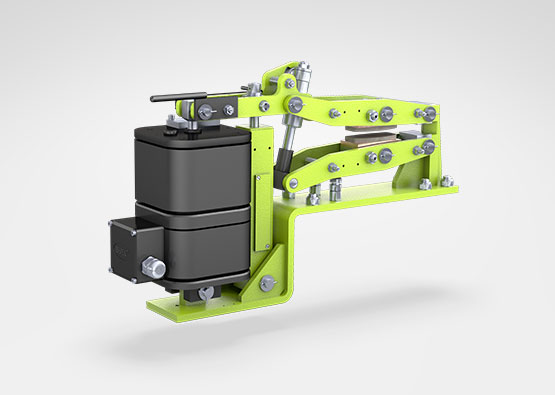

These rail clamps are storm brakes static suitable for small to medium forces. They are spring actuated; the spring exercise the closing force while an hydraulic cylinder fed by a suitable hydraulic unit provides the opening.

- Holding force up to 800 kN

- Vertical float = ± 7,5 mm (to be checked)

- Horizontal float = ± 30 mm

- Rail tolerance= ± 1,5 mm

- Opening time = 4 seconds

- Adjustable closing time (4 ÷ 12 s)

- Easy maintenance

- Emergency manual opening device

- Hand Pump

- Working temperature different from standard (-20°+40°)

- Double side flanges or upper flange (with hydraulic unit supplied separately from rail clamps)

- Flange for buffer fixing

- Hydraulic unit suitable to operate with more rail clamps

- Electrical board (on plate or box IP55)

- Limit switch which signals "rail clamps closed”

- Mechanical limit switch instead of inductive

- Wider horizontal and vertical float

- Security side stowage pins (to be inserted into suitable socket on the quay)

- Manufacturing according Q.C.P. different from our standard (Nuclear plan or special application)

- With special teeth for vertical force

- Language of documentation different from standard

- Certificates of materials (EN 10204-2.2, EN 10204-3.1 o EN 10204-3.2) for all main components

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

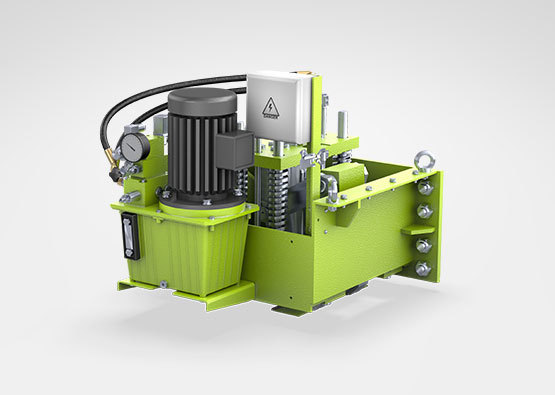

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

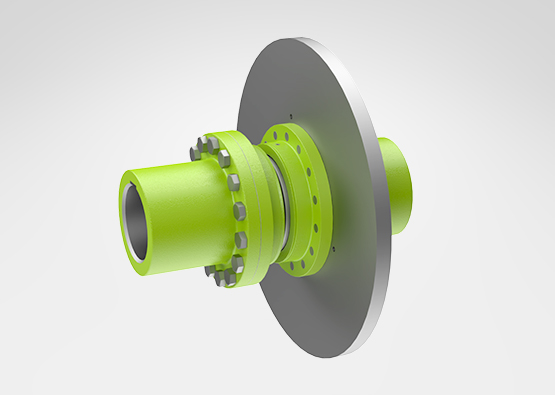

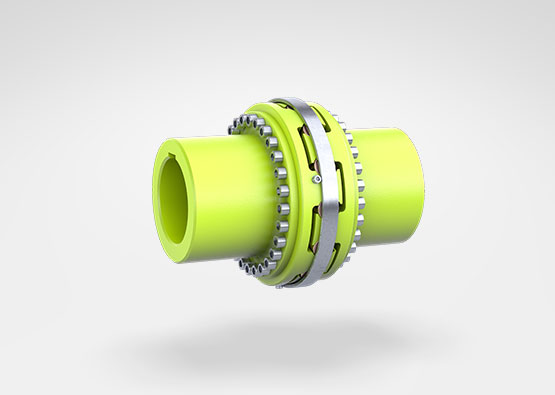

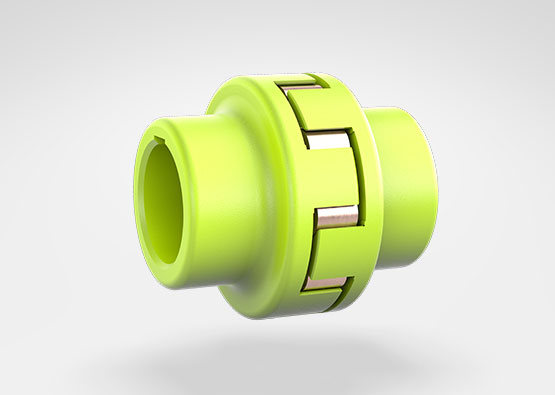

The KBSD Gear Couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

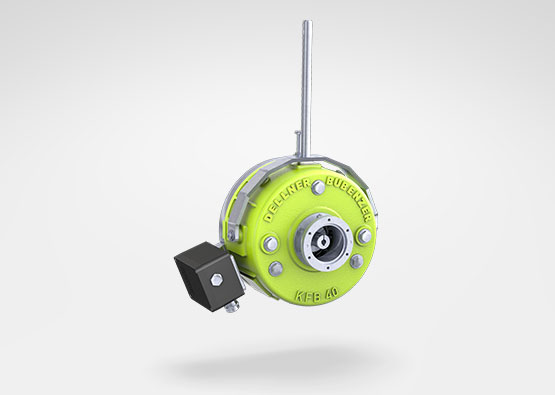

The KFB is a spring applied safety brake which is mainly used in gantry, trolley and hoisting application on harbour crane systems, in dynamic and static use at general industrial applications, in mechanical engineering, steel mills, coal mining or wind energy systems.

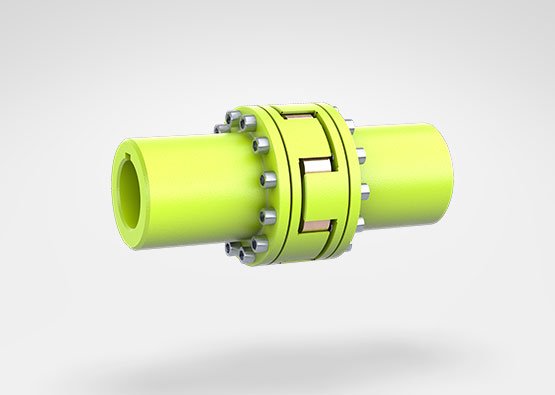

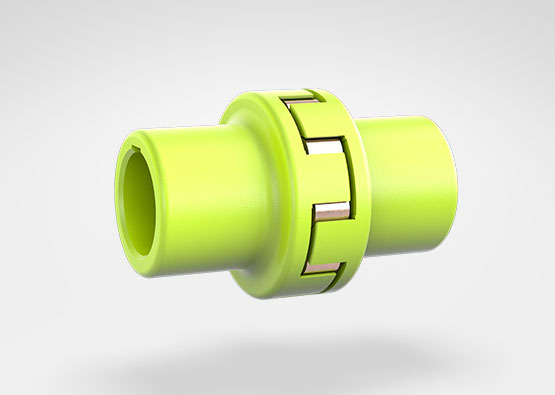

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

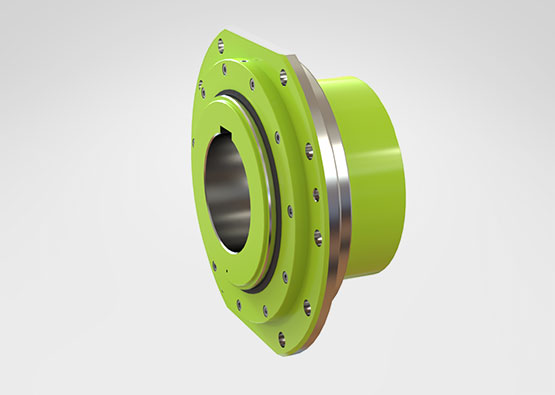

Models within LM series (locking devices) are fail safe and used to mechanically lock a rotational or linear application in a controlled position.

Models within LM sere (locking devices) are fail safe and used to mechanically lock a rotational or linear application in a controlled position.

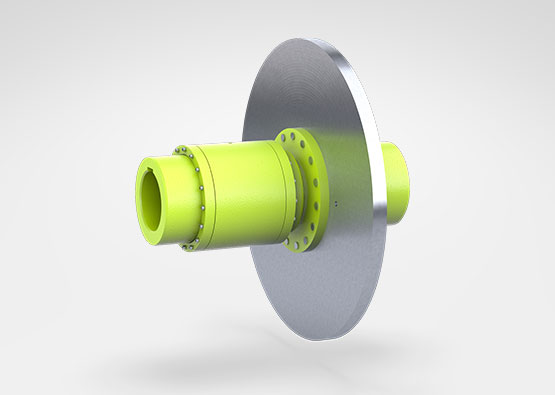

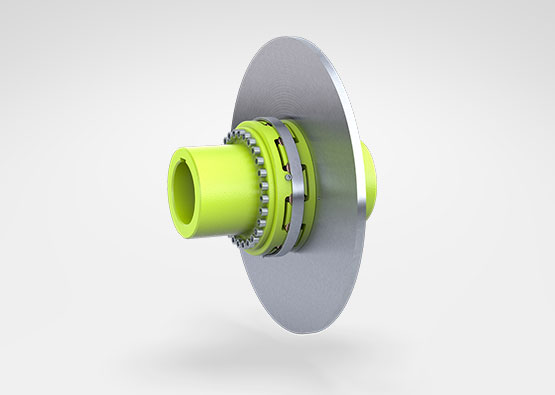

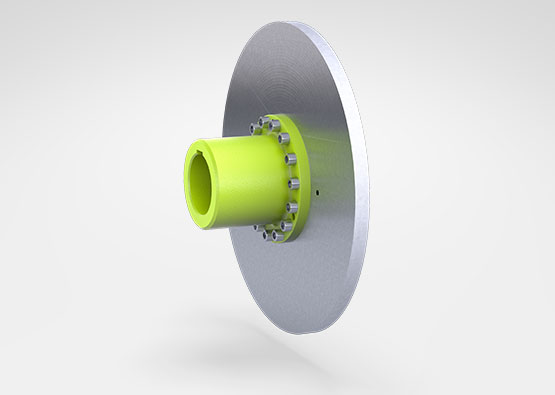

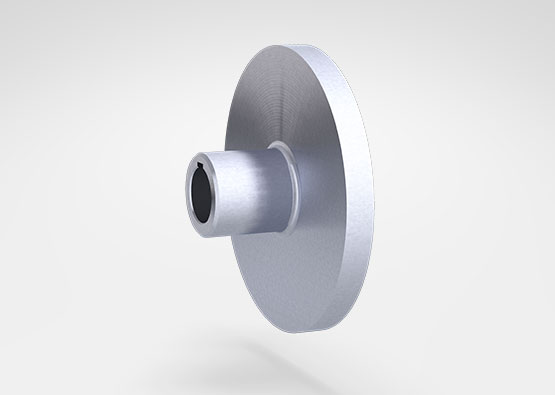

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

The NTRST Drum Couplings is a high-performance solution for hoist, winches, and conveying systems, ensuring a reliable connection between the gearbox output shaft and the rope drum. Designed to compensate for misalignments caused by bending drum structures, it enhances equipment lifespan and reduces wear.

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

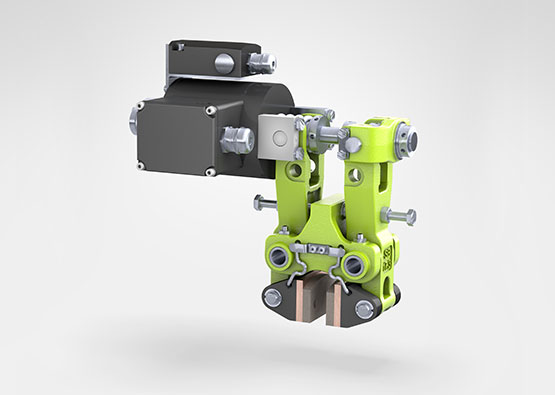

The SB 16 brake has a very compact design and is often used on trolleys for container gantry cranes, RTG and RMG equipment

The SB 17.3 MX brake is a spring-actuated, magnetic-return disc brake for trolley applications on container gantry cranes and other port logistics equipment. Furthermore, the very compact design results in a range of industrial applications in various industries

The SB series stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

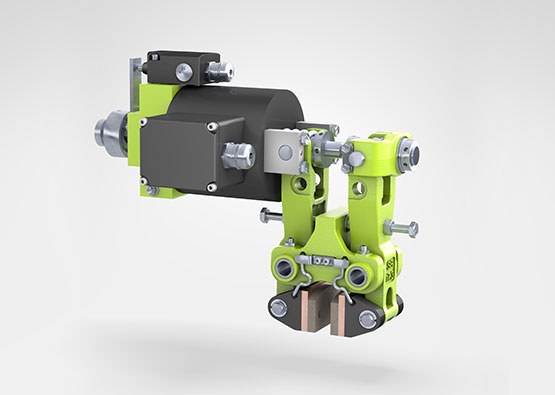

The SB 22 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 23.3 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.