BOSS®

The BOSS® Brake Only Snag System system has been developed based on the experience with the SOS system that has been already installed in more than 200 container cranes world wide. Conventional hydraulic anti snag systems have only one fixed tripping point (pressure relief valve).

The BOSS® system is working with variable tripping points (each corner individually) depending on the actual corner load measurement and hoisting speed. The BOSS® PLC is pre-calculating the perfect tripping point for each load condition. Working with the best tripping points leads to faster snag detection and less stress in the wire ropes as well as in the crane structure.

- Profisafe Interface

- Fastest reaction time

- Precise control

- TÜV certified

- Cross-check of both channels from the load pins

- Simple calibration and set-up

- Fully integrated

- Closed wired system

- Dynamic snag trip point setting depending on corner load and speed

- No maintenance time required

- Easy retrofitable

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

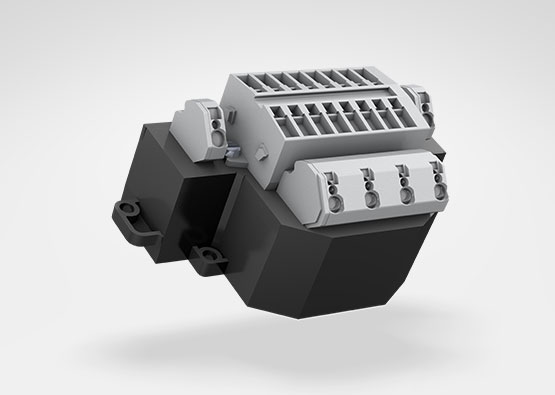

Half Wave & Full Wave rectifiers for Din rail or panel mounted rectification.

Gas-hydraulic buffers are installed as impact energy absorber on crane gantries, trolleys, elevators, stackers, reclaimers and other industrial equipment.

Protective element to be connected parallel to the output of the rectifiers BGL, EGL and SGL to increase the interurruption capacity

Din rail mounted unit switches from bridge rectification to half-wave rectification

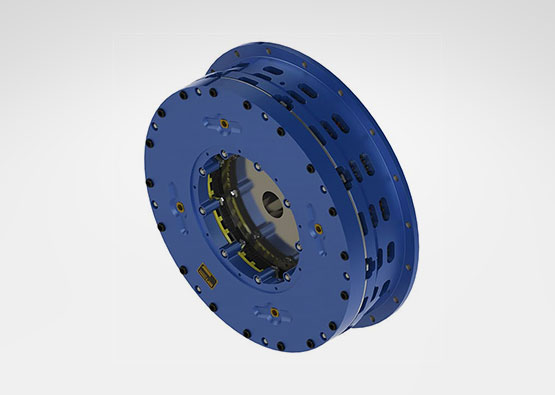

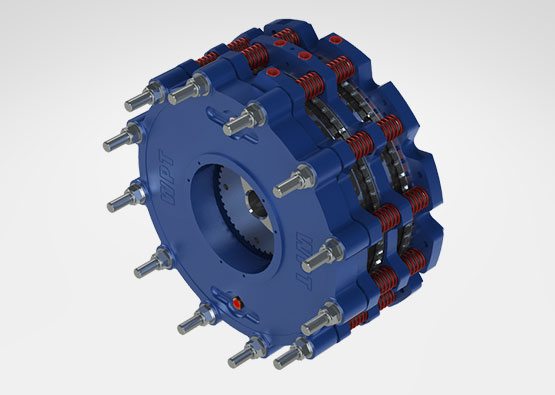

WPT Low Inertia Brakes are suited for high cycle applications or general brake duties. These heavy duty brakes afford increased precision for your processes with minimal part movement during start and stop, acceleration time is decreased leading to more cycles per minute.

WPT Low Inertia Clutches and Brakes are suited for high cycle applications or general clutch/brake duties.

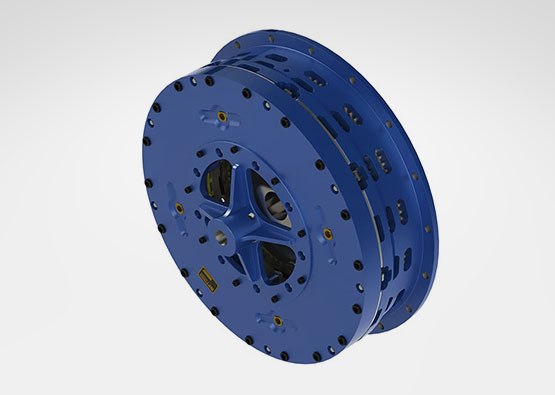

WPT Low Inertia High Torque Clutches are suited for high cycle applications or general clutch duties.

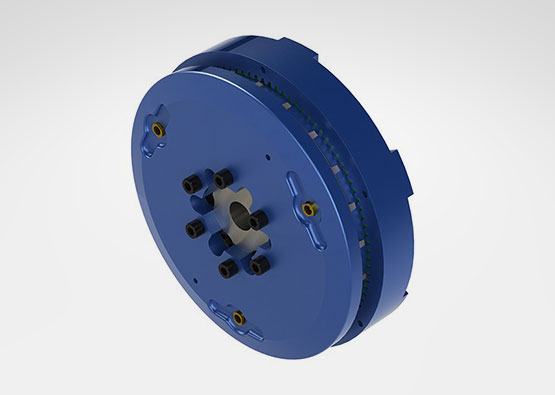

This flywheel PTO is designed for inline and sideload applications on all internal combustion engines with standard SAE industrial flywheel or flywheel housing dimensions.

WPT Power has engineered the WPT Pilotless™ Mechanical Power Take-off to eliminates the pilot bearing and increases side load capacity over previous generations of PTO products.

WPT Planetary Hydraulic Hoists are ideal for applications in the oil & gas, utility, and crane industries. WPT’s hoist designs adhere to SAE J706 standards and provide lifting capacities of 8,000 lbf and 12,000 lbf, respectively.

WPT Planetary Hydraulic Winches provide fast line speed and consistent, powerful pull capacity.

WPT® Power Grip clutches are designed to accommodate in-line and shaft-to-shaft power transmission applications with large inertia loads.

The WPT® Power Grip PO Clutch is suitable for in-line and shaft-to-shaft power transmission applications.

The WPT® Type 2 Hydraulic Power Take-Off utilizes large spherical roller bearings designed for heavier duty sideload capacity.

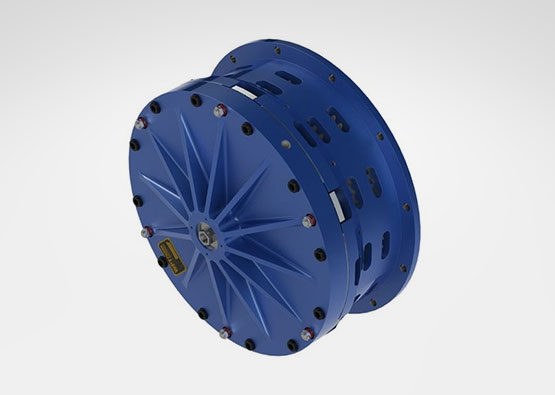

WPT® water cooled brakes (WCBs) are high energy absorbing solutions used as dynamic tensioning and static holding brakes.

WPT Worm Gear Winches are offered from 9,000 lbf to 20,000 lbf, with options of hydraulic or electric operation.